If you’re new to welding, it can be tricky to choose the right welding rods, due to the fact that there are so many options to pick from. Even experienced welders may struggle when choosing welding rods since the weld and metal can dictate which ones to use.

Luckily, we’ve located the best welding rods on the market for you to consider for the projects you have in mind. When choosing the products for our reviews, we focused on specific features. These include the price of the rods and how many were included. We also looked at the material and thickness capacities to be sure you’re using the right rods for the job. For more information on which welding rods to choose, check out our detailed reviews and buying guide below.

More features: all position welding, low spatter, best for vertical down welding, 140 Amp capacity

The Forney 30405 E6013 are some of the best welding rods we’ve found, due to their versatility and ease of use. They can be used on all types of mild steel, allowing you to complete a wide range of projects without switching rods. They can also be used in any welding position, with limited spatter and quick slag removal, so there is very little mess to clean up when you’re finished. These welding rods from Forney come in a 5-pound package that has a relatively decent price, so you can try them out without spending a fortune. There are also larger package sizes available, so you can keep more in stock if needed.

Forney is one of the top welding rod brands, with a wide variety of welding rods available for any project you have in mind. The 30405 E3016 are one of the most versatile rods they have available, giving you smooth, flat beads and a steady arc, whether you’re using AC or DC. The fact that they can be used on any type of mild steel and in any position adds to their popularity. There is a minor learning curve for beginners but even first-timers can make these rods work with a bit of practice.

More features: all-purpose electrode, deep penetration

The Hobart 770460 6011 stick electrode welding rods are designed for all-purpose use, making them a great choice for almost any job you have lined up. You can use these 1/8-inch rods in all positions, making them quite versatile, even in tight spaces. The high tensile strength means that the finished weld can handle up to 60,000 PSI of force without breaking for a strong seam. These rods even work well and give amazing results with both AC and DCEP polarities, with deep penetration and minimal cleanup when the job is done. They come in a decent-sized 10-pound package, though there are 5-pound packages available as well.

Rusty metal can be tricky to work with, as can dirty or painted materials, so you can’t just use any stick welding rods on these types of materials. Luckily, the Hobart 770460 6011 welding rods are designed to offer deep penetration when welding through light to medium materials of this type. It also works great on carbon and galvanized steel in all positions, so it is a great option for a wide variety of projects on your list. The plastic packaging doesn’t seal well, so be careful to prevent moisture from getting into it and damaging the rods.

More features: medium to shallow penetration, all-position rod, works with thin metals, 90 Amp capacity

The Blue Demon 6013 all-around welding rods are a great choice for those looking for quality results without spending a fortune. These general-purpose welding rods can be used on all types of mild steel. They are also all-position rods, so you can use them when working in almost any direction for added convenience. The Blue Demon rods can be used with both AC and DC polarities, even working well on low-voltage AC machines without issue, depositing smoothly and easily. There is some medium to heavy slag, though this is relatively easy to remove for quick cleanup.

Welder’s tools can be pricy, so finding decent welding rods that don’t cost a fortune can help you keep your costs low. The Blue Demon 6013 cellulose-based welding rods for mild steel fit this category, providing you with the perfect rods for a variety of applications. You can use them for general-purpose fabrications, machine parts, metal buildings, or any other job where there is a poor fit-up in the joint. The slim size of the rods also works well on thin metals when low heat is used. The great low price makes these rods a great choice for almost all your welding needs.

More features: all-position electrode, tack welding compatible, 90-day warranty

The US Forge Welding Electrode E6011 rods are the best welding rods for thin metals, including galvanized steel, plus they can be used on dirty, rusted, or painted steel surfaces that can’t be properly cleaned before you get to work on them. These rods even work well on heavy-gauge steel, so you can use them for almost any project you have in mind. They freeze quickly, so they are also a great choice for vertical overhead work, plus almost any other position you need to work in on the jobs you have lined up. These arc-welding rods also work with both AC and DC polarity for added convenience.

As its name suggests, US Forge is based in the United States, so those looking for their products close to home will love these rods. They are decently priced for a 10-pound package of rods, too, so you don’t need to break your budget keeping them in stock, even with consistent welding work in your future. The versatility and ease of use that these rods have to offer make them a great choice for beginners and experts alike, so you can get professional results, regardless of your skill level.

More features: tack weld compatible, low hydrogen, 90 Amp capacity

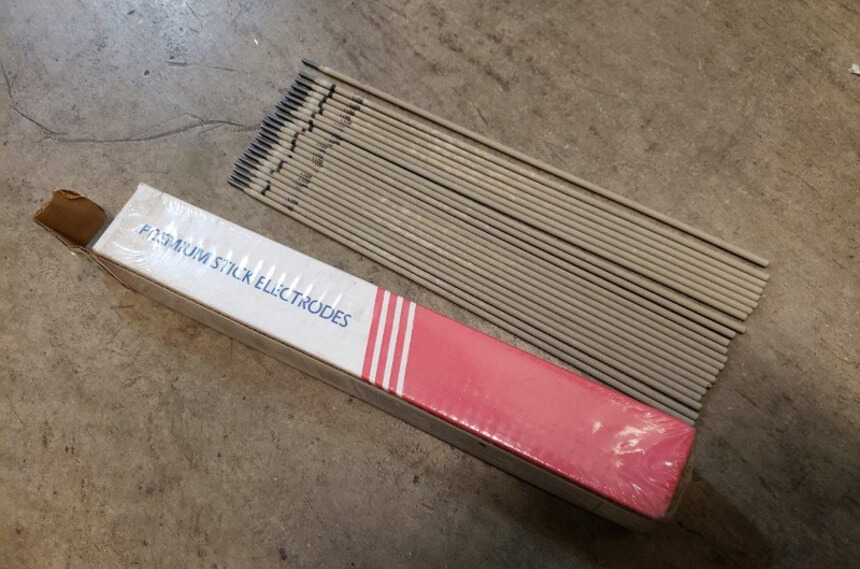

Those looking for the best 7018 welding rods may want to give the Forney 30705 E7018 rods a try. These are low-hydrogen welding rods that offer consistent results when used with both high-amperage AC machines and low-amperage DC machines. Designed for general-purpose welding, these rods are the right choice when working with any type of steel, even difficult materials, such as thicker sections or restrained joints that could have issues with cracking. The low hydrogen content reduces cracking or peeling for a cleaner look and a longer-lasting finish. It can even be used in all positions for even more versatility, even on hard steel that hasn’t been preheated.

The 7018 welding rods are the most versatile option there is, working well on low to moderate carbon steel, providing an extremely strong weld that can handle up to 70,000 PSI. It can be used in all four positions, ensuring that you can complete any project you have in mind without swapping out the rods throughout the job. These welding rods from Forney don’t cost a great deal and create minimal spatter and slag for easy cleanup. They also have a decent price without sacrificing quality.

More features: melts at 728° F, 24.9% IACS electrical conductivity, fluxless

The Alumaloy Aim rods are not your typical welding rods since they don’t require a welding machine or any specialized training to use them. They are designed to be the simplest repair tools around, with only a few steps to follow that even first-timers can get the hang of quickly. To use these rods, all you need to do is clean the surface of the base metal and then heat it using a propane torch. Once the metal is hot enough, apply the Alumaloy Aim rod to it and watch it melt. You can move it as needed to cover holes or cracks or join two pieces of metal together. These are the best welding rods for aluminum, pot metal, and galvanized steel.

These rods are best for beginners or those who want to do some repairs around the house quickly and easily with no specialized training or equipment required. They are also quite versatile, so you can use them on tools, storm doors, ladders, oil pans, RV parts, and so much more. They also have a decent tensile strength of 39,000 PSI, so your repairs should hold for as long as you need them to.

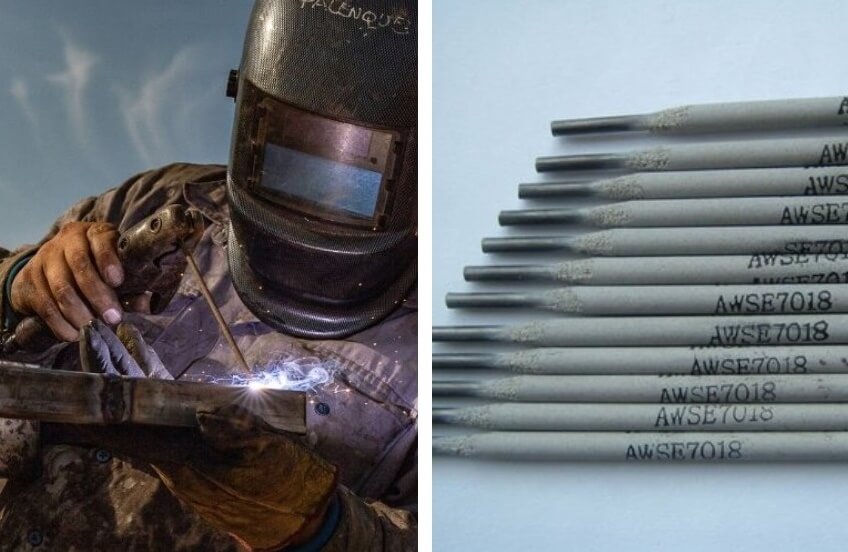

Welding rods, also called welding electrodes, are mineral-coated or metal-coated metal rods. They are used in shielded metal arc welding, also known as stick welding. The welding rods are designed to conduct electric current to the arc while providing filler metal to create a bond on the piece you’re working on. There are different types of welding rods available, with varying numbers to determine which ones are best for specific uses.

You may have noticed that welding rods have specific numbers and letters used to describe them. These aren’t randomly chosen, each of the letters and numbers has a specific meaning. To make this simpler, we’ll use the Forney 30405 E6013 as an example, with the E6013 part of the name as the focus.

The E stands at the beginning of the sequence stands for electrode.

The first two numbers refer to the tensile strength. In this case, the numbers 60 mean that these rods have a tensile strength of 60,000 PSI. A 7018 welding rod would have a tensile strength of 70,000 PSI.

The next number indicates the position of the weld. The 1 in the 6013 welding rods means that they can be used in all positions. A 2 would indicate that the rod can only be used in flat or horizontal positions, while a 4 means the rod can be used in flat, horizontal, vertical down, or overhead positions.

The last number determines the coating and welding current. These numbers range from 0 to 8. The 3 in the 6013 welding rods means it can be used with AC and DC+/- welding currents and has a high titania potassium coating. The 8 in the Forney 30705 E7018 rods has the same current specifications, though it has a low-hydrogen potassium, iron powder coating.

Welding rods aren’t interchangeable, so you need to choose carefully before picking one for the job you have in mind. Of course, no matter which ones you use, you still need a quality welder to go with them. The best Miller welders are good options for amazing results. There are also several models in the best Forney Easy Welders line if you’re partial to this brand. The following sections cover what to look for in the best welding rods.

Welding rods aren’t overly expensive, so you can usually get a 5-pound package for around $20, depending on the brand you’re purchasing. Some do cost more, though they don’t always ensure higher quality results, so if you’re on a budget, you can get cheaper rods without sacrificing your welds.

The pack quantity you should purchase depends on how often you do any welding. If you’re working in a welding shop, you likely need a steady supply of rods, so a larger pack is a must. For hobbyists or those doing some DIY repairs at home, the welding rods may last much longer. Though they won’t expire, moisture can damage the welding rods, reducing their shelf life and causing welding defects. To prevent this, smaller packs, like the 5-pound pack of Blue Demon 6013 welding rods, may be a better option.

Welding rods come in varying diameter sizes, each of which requires recommended amperages. The rod needed for a specific job depends on the thickness of the metal you’re using. For instance, a 3/32-inch welding rod can be used on metal up to ¼-inch thick. The length needed also depends on the size of the project you’re working on.

The temperature capacity of any welding rod depends on its size.

The thinner the rod, the lower temperature it will need to melt and create a bond with the base metal

The tensile strength determines how much force it will take to pull the weld apart. For instance, the Alumaloy Aim has a tensile strength of 39,000 PSI, so this much force can break the weld, while the Forney 30705 E7018 will withstand up to 70,000 PSI of force.

The penetration depth varies, depending on the type of rod you’re using. Some jobs require deep penetration to cut through dirt, paint, rust, and other surface contamination, so rods like the Hobart 770460 6011 are a good choice. Thinner metals need shallow penetration to avoid burning holes in them.

Not every welding rod works with every metal, so you need to check the specifications before choosing one for a specific job. Some rods are designed for mild steel, while others work best with high carbon steel, aluminum, or cast iron. Choosing the wrong welding rod for the metal you’re using can result in defects or broken welds.

As we mentioned above, some welding rods penetrate deeper than others, which can damage thinner materials while other metals need deeper penetration to cut through paint or rust. Knowing the thickness capacity for the rods you’re using can prevent damage and ensure a solid weld.

When choosing welding rods, there are some extra features that you may want to consider. Some rods can be used in multiple positions, making them much more versatile than other options. Welding rods that offer low spatter and minimal slag ensure less waste and faster cleanup. The Alumaloy Aim doesn’t even need to be used with a welder, though you’ll still need safety equipment, such as the best Miller welding helmet and decent gloves to protect you from burns.

Choosing the right welding rods is a must for any of the welding projects you have in mind. Though there are several to choose from, we have a few favorites that deserve a second look.

Our top choice is the Forney 30405 E6013, which comes in a 5-pound pack, has a 1/8-inch diameter, and tensile strength of 60,000 PSI. These rods are versatile, working in all positions, with minimal spatter and quick slag removal.

The Hobart 770460 6011 rods are designed to work on carbon and galvanized steel, even pieces that are painted, rusty, or dirty. They are all-purpose, all-position rods, with deep penetration.

For those on a budget, the best welding rods are the Blue Demon 6013. These have a 3/32-inch diameter, withstand up to 60,000 PSI of force, and offer medium to shallow penetration on mild steel.