Whether you are a professional or a hobby handyman, if you like to work on metals often and use a CNC table, a plasma cutter is a good addition to your tools. A plasma cutter cuts and divides hard materials precisely and quickly. Its functions are versatile, and you can be flexible using the device.

From plasma cutters with a transferring arc to non-transferring plasma cutters, hand-held plasma cutters, or machine-guided plasma cutters – there is a large selection of plasma cutters to choose from. So it’s not easy to find the best plasma cutter for CNC. Taking a look at the duty cycle, input voltage, output current, cutting ability, dimensions, and weight, and the warranty, we will give you easy-to-understand purchase advice and show you the best plasma cutters that are compatible with CNC tables. Please also note our safety instructions for the safe use of your plasma cutter.

Other features: Plasma/TIG/Stick combo; Blow-Back non-high frequency start; 14ft torch; pre-installed NPT 1/4” industry type D plug

The Lotos LTP5500D is a plasma cutter that works with a 60% duty cycle at 55 amps. The input voltage here is 110/120 voltage and 220/240 voltage while the output current is 20 to 55 amps. This is a plasma cutter that comes with a 220 plug on it. It’s a 30-amp plug, however. In the manual, it says that it requires a 60-amp breaker.

The LTP 5500 and the Primeweld CUT60 are very similar machines in terms of performance, coming from two of the top brands in the cheap plasma cutter market. The performance of the machine is getting up there with professional-style machines. The Lotus model has a 30-day refund/replacement policy and a 1-year warranty but it’s just not as good as Primeweld’s three years.

Other features: upgraded IPT-60 torch; Adjustable Post Flow timer (up to 60 sec.); digital display; 14ft torch cable

The PowerPlasma 52i from Everlast works with a maximum output of 50A and creates a clean cutting capacity of 1/2 inches and 3/4 inches. It is still operated on normal household electricity, which is certainly an advantage for many, especially since its compact design and low weight make it ideal for mobile use.

The operation is uncomplicated, it can be continuously adjusted between 20 and 50 A and convinces with a duty cycle of 60% at 50 A. The device has been redesigned to have a fully digital design. This ensures better reliability and circuit complexity. At around 42 pounds of weight and compact dimensions, the device is a bit portable.

Other features: MOSFET Inverter-powered; Blowback Pilot Torch; High-Frequency arc start

The Cut 60 from Primeweld is a powerful plasma cutter that works with up to 60A. As a result, it achieves a cutting performance of up to 1/3 inches with mild steel. You can also cut aluminum up to a thickness of 4/5 inches. At only around 33 kilograms, the device is light enough and also compact. At full load (60A) the duty cycle is 60%, which is also decent. The high-frequency contact ignition ensures clean and good ignition behavior, and you can freely set the cutting current between 20 and 60 A.

Despite the high performance, it is very compact with only around 33 pounds of weight, a bit lighter than the Everlast PowerPlasma 52i. It has a compact size of 20.5 x 10.4 x 16.5 and also impresses with a duty cycle of 60% at 46A. If you look at the cut quality between this machine and the LTP 5000, it is night and day as this machine beats it. The three-quarter-inch cut is so much cleaner on the Primeweld compared to the Lotos model above.

Other features: LCD display; ergonomic handle

The Plasmagon Cut60HF plasma cutter is a dual voltage model; meaning it works with 110 or 220 volts. It came with around 8 feet of hose for your air. It also came with the regulator for the air and the bracket that mounts it. It only comes with three sets of consumables and then some fittings for your air lines. The machine also comes with the common consumables with a good torch that has safety on it.

The device offers decent performance at an affordable price. The operation takes place on the mains power and the operation is very comfortable and uncomplicated. Thanks to its compact dimensions of 13 x 8.6 x 5 inches and a weight of around 21 pounds, the device is very compact to be able to take with you. Together with the Lotos LTP550D, it is the most lightweight in this review.

Other features: 20 ft leads included; protected air filter regulator; automatic gas adjustment

Light, compact, and with high cutting speed without leaving a slag, the Hypertherm Powermax 45 is one of a kind, allowing you to perform simple and more complicated jobs with absolute precision. It is a fast machine with cutting speeds 1.5 times faster than oxyfuel. It has a superior quality of cutting and edge preparation. The Plasma Powermax 30 cutter allows different types of cuts. You can make a flush cut and cut closer in base materials at a 45-degree angle. You also have the option of making surface finish cutting. The machine offers a long reach grooving and greater accessibility when grooving in tight spaces.

It is easy to use, has a small size, has a light weight, and offers exceptional portability for cutting equipment rated 16 mm (5/8 inches). It has a drag-cutting technology that enhances the use of the machine. The Smart Sense technology ensures that the air pressure is always regulated. It offers a good learning curve for novice operators. The CNC interface and FastConnect torch connection allow operation in manual and mechanized applications.

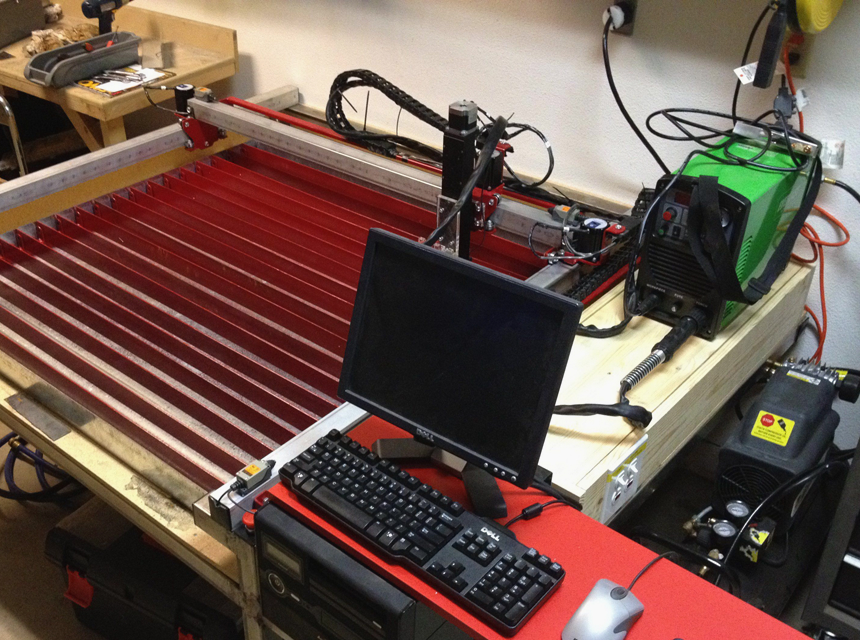

What makes specific plasma cutters suitable for CNC machines is that they are digital devices designed to be used with a computer. The computer indicates the precision of the cuts to be made, according to a digital sketch (vector image), previously made in a compatible program such as Corel, AutoCAD, Solid Works, Fusion, etc. Thanks to the electronic control technology, you will therefore be able to automatically manufacture workpieces with high precision. CNC stands for computerized numerical control. It is a computer-based, automated control of a plasma cutter. The CNC Plasma Cutter uses a high-speed jet of ionized gas (plasma), which conducts the electricity from the torch to the work material and heats the part until it melts and expels the material.

With a CNC plasma cutter, you will get different advantages during the process, and it is reflected in the result.

One of the greatest benefits of these cutters is their compatibility with different types of metals. In addition, you will have much more precise work and great cutting cleanliness, since the plasma torch expels the residues of the molten material. They are easy to operate thanks to their CNC system that specifies the exact location of the cut.

To choose the best plasma cutters for CNC, some of the key features to consider include the following:

The voltage that a plasma cutter works with is called the line voltage. Models with around 230 volts are perfectly adequate for hobbyists. A 400-volt device is particularly suitable for experienced do-it-yourselfers. Make sure to use a high voltage connection when working with professional equipment. Some models use far more electricity than others. So that the plasma cutter does not turn out to be a power hog, a comparison of the average energy values of the devices under consideration should be made before buying.

The duty cycle, also known as the power cycle Trusted Source Duty cycle - Wikipedia A duty cycle or power cycle is the fraction of one period in which a signal or system is active. Duty cycle is commonly expressed as a percentage or a ratio. A period is the time it takes for a signal to complete an on-and-off cycle. en.wikipedia.org , in welding is a period when the signal of the plasma cutter is active; that is, a period it takes for the signal to finish an on and off cycle. It is usually expressed as a ratio or percentage. For example, the duty cycle of the PRIMEWELD CUT60 is 60 percent at 60 amps. This value means that the plasma cutter can work for 5 to 7 minutes within 10 minutes.

There are three ways of cutting with a plasma torch: drag cutting in slow implementation close to the workpiece, distance cutting for penetration work, or furrowing and drilling. The maximum cutting thickness indicates the highest possible thickness of the material to be processed. Commercially available models can usually process material that is 15 to 20 mm (0.6 to 0.8 inches) thick. Powerful plasma torches also cut through 35 to 40 mm (1.4 to 1.6 inches) thick metal.

Plasma cutters for CNCs are digital devices and there is no way we can talk about digital technology without the use of a control panel or display. The display shows the duty cycle, air pressure, among other data. The Everlast PowerPlasma 52i and the PRIMEWELD CUT60 for example have good display systems that ensure the digitalization of your work.

If you need the plasma cutter primarily for work at home, you can buy a heavy-duty plasma cutter. However, if you want to be flexible and mobile, a device with a lower weight of around 10 kg is recommended. So that your plasma cutter is easy to transport, you should also pay attention to the dimensions. Compact and lightweight, the device can be taken anywhere.

An important criterion for the longevity of the device is the quality and processing of the material from which the plasma torch is made. Seals of quality give the assurance that you have chosen a high-quality device. A sign of reliability and durability is also the warranty. Most brands offering this include a warranty coverage between 1 to 5 years. Lotos LTP5500D comes with a 5-year warranty while the Everlast PowerPlasma 52i has just a year of warranty. However, you should note that the more premium the quality is, the better the warranty coverage.

The craftsman or do-it-yourselfer connects the plasma cutter to a power source via the electric cable. The connection to the device and a clamp for the material are usually located on the earth cable.

The rear panel of CNC plasma cutters has machine interface connectors that you may hook your automated torch to.

However, the interface port that you wish to use for your CNC cutting table only works if you’ve removed the hand torch. So, you cannot keep the two torches plugged in.

The electrically conductive plasma is created during the ignition process. With a temperature of up to 30,000 degrees, the plasma cutter can process metal precisely.

You must make slow movements with the plasma cutter. Since the gas contained is ionized, it reacts very quickly and cannot cut cleanly and precisely if it is moved too quickly.

If users are not that technically experienced, they should leave the usage and maintenance to a specialist who follows the specifications in the operating instructions precisely.

To ensure a long service life for the device, the following points should be taken into account during maintenance:

Before you start using the plasma cutter, you should read the manufacturer’s instructions carefully and take all necessary safety precautions. The greatest dangers to avoid are:

Electric shock: The risk of electric shock is reduced if the plasma cutter is connected as described in the operating instructions and only the accessories supplied are used. Live parts and electrodes must not be touched without gloves! The protective clothing should not be wet, otherwise, it would conduct electricity.

Development of smoke and gases: There should be good ventilation in the room in which the plasma torch works. Inhaling gases can be harmful in the long term. Ideally, the workplace must have an air extraction system.

Risk of burns: There must be no flammable materials near the work area. A small flight of sparks through the plasma torch could be enough to start a fire. Users should protect their skin with appropriate protective clothing.

Risk of explosion: The workplace environment must be free of explosive gases or flammable liquids. All parts and accessories of the plasma torch must be handled with care.

Impairment of a pacemaker: Since magnetic fields are generated Trusted Source Plasma Cutter Awareness Reminder A plasma cutter can be hazardous when improperly used. Incidents could include electric shock, fire, or personal injury. www.bu.edu when working with a plasma torch, the function of a pacemaker could be impaired under certain circumstances. Users with a pacemaker should seek the advice of their doctor before starting work with the plasma cutter.

Rated 9.9, our Editor’s Choice is the Lotos LTP5500D. The plasma cutter is a combination of a plasma, TIG, and stick welder. It works with a 60% duty cycle at 55 amps. It’s our overall best plasma cutter for CNC.

We think the Everlast PowerPlasma 52i has the best easy-to-use CNC port. It’s rated 9.7 out of 10. It can be continuously adjusted between 20 and 50 A and has a duty cycle of 60% at 50A. The device has been redesigned to have a fully digital design. This ensures better reliability and circuit complexity.

With a rating of 9.4, our Best Value pick, the PRIMEWELD CUT60 is a powerful plasma cutter that works with up to 60A. As a result, it achieves a cutting performance of up to 1/3 inches with mild steel.