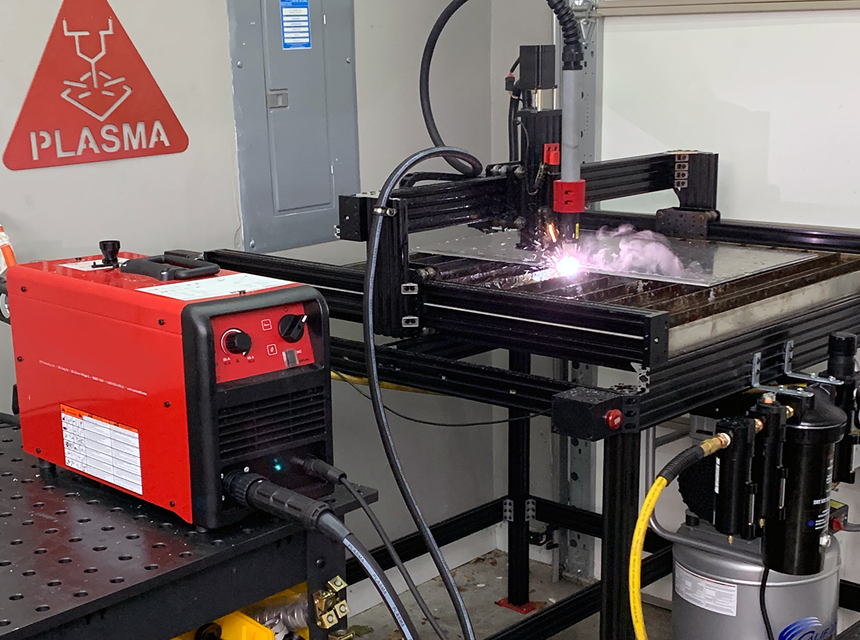

At first look, they look like inverters or stabilizers; but no they’re not! They perform tough jobs and are often deployed for productive uses that involve metal works. Depending on which material you need it for, there is a choice between different models with different cutting abilities or thicknesses. But is it possible to get a quality plasma cutter on a budget? Let’s find out!

In our guide on best plasma cutter under $300, we took a close look at ten models and presented their respective features, which include the cutting ability, duty cycle, efficiency, size, and weight. Below, we will explain a lot about the benefits of plasma cutters and present to you some purchase criteria. Before reading the reviews of what we consider the best cheap plasma cutters on the market, take a look at them in the quick comparison below.

Other features: MOSFET transistors; High-frequency DC Plasma; 3-year warranty

Whether you are cutting on rusty metal and alloy, or metal, expanded metal, the pilot arc of this PrimeWeld CUT50D will allow you to cut it effortlessly.

The machine with a 60% duty cycle can do a short job of 1/4 inch steel, quickly creating a new cut. However, it may start to slow down once you start cutting 1/2-inch thicker alloy plates.

It is backed by a 3-year warranty which is much better than that of competing plasma cutters at this price range. We liked its extra-long 19.6-foot flashlight cable, but the power cable was quite short and made life more difficult.

Nonetheless, it will work with 220V and 110V.

Other features: MOSFET transistors; efficiency is increased by 30%; Pulse-Width-Modulation (PWM) technology

If your main requirements are to start plasma cutting and have a cheap, good quality cutter, the LT5000D from LOTOS could be the best option for you.

It only weighs around 22.5 pounds, which means you can easily move it from project to project. However, be careful not to underestimate the power of this cutter. It is fully capable of cutting almost any type of metal or alloy up to 1/2-inch thick with its 9 feet and 9 inches cutting torch.

Rated for a 1/2-inch clean cut and 3/4-gap thickness, an air compressor rated at 3.8 CFM at 66 PSI is recommended, but users have had success using small-type compressors rated around 3 CFM.

The small chassis draws up to 50 amps of current, and that’s more than enough for just about any cutting job you need to get done. This unit also features a patented cooling system to help you work faster and longer.

The length of the torch cable is a bit disappointing so you will need to reposition a bit more while working. Also, while the price is low for the up-front, be prepared to spend a bit more on consumables than some of the more expensive units.

Other features: digital LCD; easy-read front panel air-pressure gauge; PRO technology; eco-efficient operation

If you are looking for a cheap plasma cutter, you might be happy to sacrifice performance to purchase an item.

This device contains dual voltage capabilities, so it can run on 220V or 110V electricity. It has a digital LCD, an easy-to-read air-pressure gauge on the front panel, an integrated PRO technology and works ecologically efficiently.

If you like to cut metal thicker than ⅜ of an inch, you will have to look elsewhere. At this depth, the machine cuts slowly and the result is somewhat rough. It constantly overloads and turns off, which means you’re going to stop every two inches.

Other features: 0.5 in ideal cut thickness; 0.75 in severance cut thickness

The VIVAHOME CUT-50 plasma cutter achieves an ideal cutting thickness of 0.5 inches. It has an electrical display and a fan is integrated. The device has a nominal power voltage of 110/220 volts. The plasma cutter achieves 60 percent at 50 amperes in one work cycle.

The shipping weight is 23 lbs. The input power is up to 4.8KVA and it operates at a no-load voltage of 230 voltage. The rated output current is 20-50A. It has a motor that runs up to 1300 revolutions per minute.

The package includes an LG-40 cutting torch, an earth clamp, an AIR Regulator, two pieces of plasma tip, a PG head, two gas pipe claspers, a hoop, an English manual, a chipping hammer or wire brush, a face mask for welding, a valve for reducing pressure and a piece of googles.

Other features: LED digital display; pressure gauge; strap included

The SUNCOO CUT50 plasma cutter has a maximum cutting thickness of 12 millimeters. It has an integrated inverter technology, which is characterized by its high performance with less power consumption. The air pressure value appears on the digital LED front display. According to the manufacturer, the plasma cutter can cut copper, carbon steel, iron, aluminum, and stainless steel.

With the extensive range of accessories, work can be started immediately. The only thing that requires a separate connection is a compressor.

The cutting current adapts to different materials. The duty cycle of the plasma torch is 60 percent. For safe working, the plasma cutter has protective devices against overheating, overvoltage, and undervoltage.

With dimensions of 15.6 x 6.1 x 9.8 inches and a weight of 25.4 lbs, the device can be used flexibly in different locations. The package includes an air regulator, a hose clamp, a gas hose, a nozzle, and a grounding clamp.

Other features: digital inverter plasma cutter; NPT 1/4” industry type D plug pre-installed

The Lotos LT3500 plasma cutter is light and compact with a size of 14 x 5.5 x 9 inches and a weight of 17.5 pounds, making it quite a portable pick. The plasma torch has a maximum output power of 35 amps.

The cutting strength of the plasma cutter from Lotos is a maximum of 2/5 inches in clean cut and 3/5 inches in severance cut.

The plasma cutter has an integrated inverter. This is a modern technology that, according to the manufacturer, will help produce a high level of performance. There is no separate transformer and no MOSFET required.

It’s best for thin metals, but it’s a lot more effective and better than using a grinder or hacksaw.

Other features: current display; IGBT inverter soft switch technology

The hynade HYC-50D plasma cutter is a portable device with a weight of 21 pounds and dimensions of 14.2 x 6.1 x 13 inches. An external compressor, which should have a pressure regulator, is required for use. The plasma cutter has a quick coupling system so that the compressor can be connected easily, and the required pressure is given.

The plasma torch also needs an amount of air between 90 and 180 liters per minute to work. The device ignites when it comes into contact with the material.

The plasma cutter is a good entry-level device for private use thanks to its safe and easy handling.

The cutting thickness of the plasma cutter with an integrated inverter is 14 millimeters maximum. According to the manufacturer, it works with modern IGBT technology and a high-quality cooling system, which should offer a long duty cycle of 60 percent and uncomplicated work.

IGBT is the abbreviation for Insulated Gate Bipolar Transistor. It is a semiconductor device that is often used in high voltage and high current applications.

It’s ideal for non-straight cuts. Understanding its operation and practice would be an asset. The device is more efficient with 220 volts.

Other features: voltage compensation; 85% inverter efficiency; PWM controlled output

The Mophorn CUT-50F plasma cutter works based on a pilot arc technology. The maximum output current is 50 amperes and can be continuously adjusted to different materials. According to the manufacturer, the device cuts through materials up to a thickness of 14 millimeters.

With dimensions of 14.6 x 5.9 x 9.1 inches and a weight of just 11.5 pounds, the plasma cutter is one of the most compact cutters that are suitable for flexible use.

An air regulator prevents overheating, overpressure, and overcurrent while working. The machine also has an IP21 level of protection. Asides from the plasma cutter, a cutting touch, grounding clip, oil-water separator, hose clamps, gas joints, a nozzle set, an electrode set, and a manual are included as accessories and additional support for the plasma cutter.

Other features: non-touch pilot ARC; digital display; alarm LED

This is a plasma cutter with a pilot ARC whose tip is designed not to be touched. The TOOLIOM TL-50C uses an inverter system with IGBT technology. It’s a plasma cutter with a 60% of duty cycle.

The ergonomic handle and a guide spring should ensure better handling. The plasma cutter is designed for cutting steel up to 12 millimeters thick. The device cuts electrically conductive materials such as brass, copper, steel, aluminum, and stainless steel.

The dimensions of the device are 11.8 x 16.14 x 6.3 inches. It’s more compact when unpacked. The weight is given as 22.4 pounds. The scope of delivery includes a ground cable, a hose package, an air pressure regulator, a torch and supply line, and more.

Other features: transfer efficiency above 85% under good conditions; SG-55 cutting torch; advanced German colling system

The plasma cutter from SUNDGOLDPOWER has a high-performance cycle that makes the device consume less electricity compared to traditional cutting machines. In terms of efficiency, this cutter has a high speed, high temperature, and the use of high-energy plasma.

Also, thanks to its modern technology, this cutter does not cause any noise and enables the smoothest possible cutting.

This means that subsequent polishing is no longer necessary. The cutting current can also be adapted to cutting requirements.

The machine can make 0.5 inches clean-cut and 0.75 inches severance cut. The transfer efficiency is above 85% during normal conditions. It’s equipped with an SG-55 cutting torch with an advanced German cooling system.

The device is connected to the power source by an electric cable. The connection to the device and a clamp for the material are usually attached to the earth cable.

The ignition process creates an electrically conductive gas – the plasma. Because of this type of generation, a plasma cutter has a temperature of 30,000 degrees celsius on the plasma. This is the only way to burn conductive metals with pinpoint accuracy.

Before the cutting process begins, you must first place the cathode on the material. Then the circuit is short-circuited.

With the help of the compressed air, the nozzles of the plasma cutter can rise slightly, creating an arc. The plasma cutter can now ignite and the cutting current increases. From now on, the plasma cutter begins to penetrate the material.

Tip: The material can be easily processed and cut using an electric arc.

The plasma cutters usually do not have an integrated compressor but the connections for it. For the plasma cutter, the compressed air must be fed in from an external compressor. If this is not possible for you, you should look for a plasma cutter with a compressor.

The eponymous plasma is the gas. Plasma is sometimes called the fourth state of matter (next to solid, gaseous and liquid). For example, in pure nature, lightning is a good example of plasma. Lightning is also just a discharge of electrical voltage through a gas.

Plasma is also a conductive gas, which means that it can conduct electricity. The arc is mostly kindled by ignition and tied through a nozzle made of copper.

In the arc itself, a jet of plasma is then formed from the compressed air gases. This causes the respective object to melt, but the energy of the beam immediately pushes the liquefied component of the object out of the cut area again.

These special cutting devices cut metal and other hard and electrically conductive materials with a thickness of up to 40 millimeters. A plasma cutter has the advantage over other cutting tools such as laser cutters because it has a very high cutting quality.

A plasma cutter is essential for processing electrically conductive metals. It works so precisely and cleanly that post-processing of the workpiece is hardly necessary and efficient work is possible.

Plasma cutters are also known as plasma torches because they work with a hot gas that can reach temperatures of up to 30,000 degrees when cutting.

The models in the under $300 range weigh around 22 pounds on average. They are easy to transport and usually come with a power source, an earth cable, a power supply, a compressed air supply, and electrodes.

You connect the plasma cutter to a power source via the electrical cable. The connection to the device and a clamp for the material are usually located on the earth cable.

The electrically conductive plasma is created during the ignition process. With a heat of up to 30,000 degrees, the plasma cutter can precisely process metal.

However, for models within the indicated price range, the cutting thickness on metal doesn’t usually go past 15 millimeters. For example, the hynade HYC-50D and the Mophorn CUT-50F have a thickness capacity of 14 millimeters. However, the more premium ones can easily reach 40 millimeters.

To ensure that the plasma torch fulfills the purpose for which it is intended, the following points should be compared for the various models that interest you.

Purchase criteria such as the cutting thickness, the material, power consumption, possible uses, voltage, compressor connection, and the built-in technologies should play a role when buying. In the following, we explain what these aspects are all about and which model fits which needs, and which power connection.

Also, plasma torches can be divided into:

The mains voltage is the voltage with which a plasma cutter works. Most devices have an output of 110/220 volt. Others have up to 400 volts. A high voltage connection is required to work with 400 volts.

Plasma torches with an output of over 400 volts are more suitable for professionals. For DIY enthusiasts, a device with a voltage of around 220 volts like the PrimeWeld CUT50D is sufficient.

and thickness of the material that the device is to process. The device requires more power for cutting steel than for processing sheet metal.

The cutting thickness of a plasma torch indicates the maximum thickness of the material to be cut. Devices with very high performance have a cutting thickness of 35 to 40 millimeters. On average, and for models under $300, plasma cutters can make around 15 to 20-millimeter cuts.

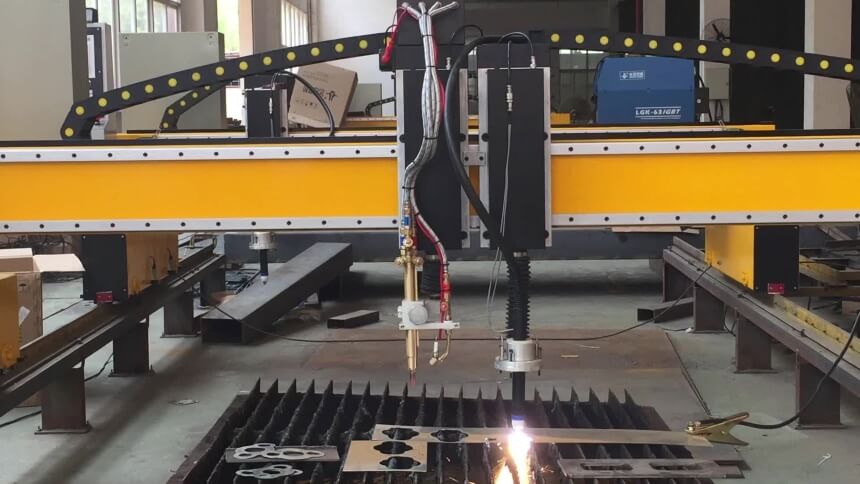

Due to the high operating temperature and the ability to process conductive metals with pinpoint accuracy, the plasma cutter is used in many areas of daily life. First and foremost, in the metal processing industry, but also in the field of rescue services, the plasma torch is indispensable today.

Classic areas of application are:

Rescuing the seriously injured, also with the help of hydraulic tongs and prying devices, often requires a plasma cutter to cut through body parts quickly and without any further risk of injury to the casualty.

But plasma cutting devices are also enjoying increasing popularity in the private sphere. The reasons for this are of course the falling prices for entry-level models in recent years and the many advantages that a plasma cutter has to offer in direct comparison with a so-called Flex.

Whether for the hobby workshop or various work in the garden, on the farm or during renovation. If conductive metals are to be processed with pinpoint accuracy and low accident rate, a plasma cutting device also offers numerous advantages in the private environment.

Also, you can assume that every plasma cutter has something like an area in which it is specified how high the respective cutting current is. In this interval, it is then possible to set how high the cutting current should be. This means that the higher the cutting current is set, the higher your cutting strength.

The compressor is needed because it has to supply your plasma torch with enough compressed air for the entire duration of your work. What is meant by a compressor connection? This question is easy to answer, because the compressor is simply the part that can compress a gas (e.g. air).

Air is also the gas that is most commonly used in plasma cutters. Actually, the compressor does nothing more than compress the air in order to then output it again with increased pressure.

It should also be noted that there are plasma cutters with integrated compressors. However, most types of plasma torches do not have built-in compressors, so they require an external air supply.

Plasma cutters that have a compressor built in are often more expensive than devices that do not have an integrated compressor, even if you save yourself the search for a compressor and don’t have to lug it around.

However, keep in mind that this rarely affects the performance of the plasma cutter.

Some models use far more electricity than others. So that the plasma cutter does not turn out to be a power hog, a comparison of the average energy values of the various devices should be made before buying.

Will the plasma cutter always be used in the same place or rather flexibly? If it is to stay in place and there is no transport, the weight does not matter. With flexible use, how many pounds the device weighs should play a bigger role.

The most lightweight models like the Mophorn CUT-50F can weigh between 10 to 12 pounds while the models intended to be used in a fixed position, further adding to the built-in technology and features, can weigh as much as 25 to 30 lbs.

Additional accessories may be necessary, which are included in the scope of delivery in the best case. Regardless of where the plasma cutter is used, protective goggles and gloves are always necessary for protection. And you have to note that these will contribute to the weight.

The warranty is an assurance of the reliability and durability of the device. With plasma cutters within the under $300 price range, some brands don’t offer warranty coverage. But it is best to pick a model that has coverage. The ideal warranty coverage is between two to five years. As a reference, the PrimeWeld CUT50D comes with three years of warranty.

The input current is the highest level of current that your plasma torch can draw. The input current is measured in amperes (A) and, depending on the device, is a maximum of 20 to 40 A.

The airflow shows you the following: it shows you how many liters of air must be consumed by your plasma cutter in one minute. How much airflow your plasma cutter needs is of particular importance when purchasing a particular compressor.

The frequency describes the level of activity with which your plasma cutter works. There are plasma cutters that work with a high frequency and plasma cutters that work with a lower frequency. The frequency is measured in Hertz. Special ignition devices use a voltage of up to 10 kHz (kilograms of hearts).

The igniters that work at such a high frequency are used to ignite the pilot arc. However, you should make sure that there are no computers, laptops, or other high-quality electrical appliances nearby. Because if you ignite the pilot arc, the use of the high frequency can seriously affect these devices.

Your plasma cutter should be equipped with the so-called inverter technology as best as possible. The inverter is the part of your plasma cutter that is responsible for converting direct current into alternating current. This happens because the plasma cutter absolutely needs direct alternating voltage to generate the arc.

Rated 9.9 out of 10, the PrimeWeld CUT50D is our Editor’s Choice. It can easily and precisely cut through metal and alloy as well as expanded metal. With a 60% duty cycle, it is our overall best plasma cutter under $300.

With a rating of 9.8/10, the LOTOS LT5000D is fully capable of cutting almost any type of metal or alloy up to 1/2 inch thick with its 9 feet and 9 inches cutting torch. It is our choice of the best budget plasma cutter with integrated inverter technology.

The Zeny CUT 50 has the best value for money out of the lot. It contains dual voltage capabilities, so it can run on 220V or 110V electricity. It also has a digital LCD, an easy-to-read air-pressure gauge on the front panel, and works eco-efficiently. It is also rated 9.8 out of 10 by our experts.