A substandard welder is a catastrophe for your welding projects. Unfortunately, some pay for the device, have it delivered, then find out quality is nowhere near good enough when it’s too late. Nonetheless, the best 120V welders are still available in a difficult to navigate market. Finding them is like walking a tight-rope. If you get even one feature wrong, you can be right back to the drawing board.

The process types used to attach the welds, max power outputs from the machine, duty cycles, and material thickness the welder can handle are a few critical features. If you have enough welder data concerning these features, you’ll know how it works. Further, you’ll determine its capabilities in handling your most challenging projects. Physical welder machine properties, e.g., weight and dimensions, also factor in. If the welder is easier to store or to transport, all the better. The bottom line is that a healthy mix of convenience and functionality is needed in the best 120V welders. Finding that in the welder machine options below is less challenging since all the pros and cons of the inventions are included.

Other features: multi-voltage, a dual-groove quick-change drive roll, built-in gas solenoid valve, dual-gauge regulator with gas hose

The Hobart Handler 210 MVP is undoubtedly a valuable player in the MIG welding market. For those unaware, MIG welding is quite delicate. Anything from rust to wind or paints on the metal can prevent you from getting an effective weld. This is why MIG welding is done in a controlled environment.

Additionally, this welder’s power output is awe-inspiring. This should be instrumental in making light work of your welding sessions. Taking a quick look at the other 120 volt welders listed below shows this MIG option is quite heavy in comparison.

Given its need for controlled environments, you might not want to transport this welder as much. Nonetheless, if a job that needs this comes up, it’s possible to put it in a car’s trunk and drive it to wherever it’s needed.

The duty cycle is adequate, although not very impressive. Additionally, control over output parameters thanks to the solenoid valve and dual-gauge regulator is a serious advantage. With this feature at your side, you can achieve better bead performance. Of course, less spatter overall is required for this to happen.

At the welder’s peak, this machine will bring together up to 3/8” steel. Another noteworthy feature is the welder’s ability to keep the feed wire electrically cold when the user’s finger is off the trigger. This leads to dual benefits, including safety and ease of use.

What we liked: Enhanced control over welding parameters can help get cleaner job results. This machine can weld up to 3/8” mild steel, which is relatively large. High maximum power output means welding doesn’t take as long. The three-year warranty helps. The trigger design allows for safety and ease of use.

What could be better: The welder is moderately heavy; hence moving it is a hassle. Also, if it supported more welding processes, it would be a better option overall.

Other features: AC/DC, 50/60 Hz, user-friendly interface, Pulse feature

As for the Lincoln Electric Square Wave TIG 200, it is about twice as pricey as the Hobart Handler 210 MVP 120v MIG welder. Additionally, the premium pick welder supports both stick and TIG welding.

Speaking of stick welding, it is one of the better options for repairing already assembled metal devices. This is because handling painted and rusted metal is child’s play for stick welders.

Additionally, if the repair job is outdoors, you can still use the welder with some acceptable results. The machine’s TIG welding capability is also not lost on us. If you use TIG welding on the Lincoln Electric Square Wave TIG 200, you are almost guaranteed clean weld results.

Further, choosing TIG or Stick welding in this machine will unlock varying output and duty cycle results. Considering the welder is usable both indoors and outdoors, having it weigh significantly less than the editor’s choice is a huge help.

Another benefit associated with TIG welding is the AC frequency control functionality. With this, you can choose more penetration in your weld or opt for more cleaning action. The “more cleaning action” option delivers excellent results when handling dirty aluminum.

This welder’s compatibility with AC sockets additionally works in most user’s favor. They can plug it into any socket they see fit and start welding. On the other hand, DC compatibility has also been included. Using it with a battery while on site is thus not far-fetched.

A user-friendly welder interface is as well very welcome. Finally, an LCD display, control dial, indicator lights, and weld process button are a few of the items in the easy-to-use interface of the welder.

What we liked: An easy-to-use welder makes welding less complicated. It features both TIG and stick welding and thus can be used for various welding tasks. Its AC/DC compatibility is commendable.

What could be better: With all its benefits, this welder is simply not affordable for most buyers.

Other features: no gas required, torch wrap, infinite voltage, and wire feed speed control

Next is the Forney Easy Weld 140 MP 120V arc welder. Notably, this is a multi-process welder, and consequently, capabilities such as MIG, TIG, Stick, and Flux-cored welding are all incorporated.

This is hugely advantageous since the weaknesses of each welding process are offset by the other processes included. The versatility of this welder is thus unmatched.

Where welder power is concerned, the output is rated at between 10 and 140A. The power you choose will depend on the welding projects at hand. Further, with all the welder’s capabilities, it is crammed within a body that weighs about 20 lbs.

Add to the welder’s positives list the fact that you have control over wire feed speed and voltage, and you’ll see another reason for this invention’s impressiveness. Additionally, you don’t need to purchase argon gas to use this welder. As such, affordability, in the long run, is guaranteed.

This being a relatively portable welding machine, duty cycle statistics are as well important. You’ll see ratings such as 30% @ 80A for stick, 30% @ 110A for TIG, and finally 30% @ 90A for MIG.

The warranty that serves buyers for six months is not likely to impress many of you since other welders have longer warranties. However, it is still possible to overlook that in favor of the welder’s other premium qualities.

What we liked: The Forney Easy Weld 140 MP welder’s FIG, TIG, Stick, and Flux-Cored welding support is its most impressive aspect. Weight-wise it isn’t shabby for a person who likes to move around. The controls that affect welding output, such as wire speed and voltage adjustment, are a plus.

What could be better: Warranty coverage seems relatively short.

Other features: dual voltage (120/240V), 1/8” max. Stick electrode diameter

Giving the other welders a bit of competition is the Everlast PowerArc 140ST. This option counts as both a Live Lift Start TIG welder as well as a Stick option. Consequently, the 10-140A for 240V and the 10-80A for 120V outputs cater to both these process options.

Additionally, the same portability levels in the Forney Easy Weld 140 MP are expected to carry over into this invention where weight is of concern. However, the dimensions are as well notably smaller in this option.

Another important consideration is the size of metals this Stick and TIG holder can handle, which is a maximum of 3/8”. Build quality for the welder seems top-notch and is supported by a five-year warranty. Lastly, this machine’s dual voltage capacity and ease of use make it a worthy purchase.

What we liked: We love the five-year warranty. Also, Stick and TIG welding does up the capabilities of this welder above the functionality of a single process device. Additionally, being able to weld 3/8” metals is impressive. Lastly, the weight and size are just right to make the welder easy to move around.

What could be better: Customers may be disappointed with the customer service if they need it. Some quality issues also seem rampant with the model.

Other features: dual voltage, all-metal case, generator friendly, portable

The lightest welder on this list is the Forney 291 Easy Weld 180 ST. Inside the device’s 14-pound chassis is support for TIG and DC Stick welding. In addition to its lightweight body, a handle that acts as a cable wrap is included. This takes its portability a notch higher.

When working on thinner metals, it’s generally better to avoid using the Stick welding option. Nevertheless, the maximum weld thickness allowed by the device is ½” with mild steel as the metal being worked on.

Like the Everlast PowerArc 140ST, this welder is also a dual voltage welder option. This means it’ll accept both 120V and 230V power source options. However, the socket option you choose or the one available to you does affect output.

The 120V power option, for instance, will lead to a 35%@80A duty cycle. This contrasts to the 25%@180A duty cycle seen when the 230V power source is available.

Additionally, the welder can derive power from a generator and still produce impressively stable welding arcs. You might have noted the “easy weld” component of the welder’s name. It lives up to this billing by having minimal controls that are easy to operate.

As for the all-metal case, you might love that it is quite durable.

What we liked: A durable exterior welder construction is a plus. This welder, thanks to the simple controls, is easy to use. Further dual voltage and dual welding processes are a plus. Being able to use the welder by deriving power from a generator may come in handy when traditional electricity is unavailable. Lastly, a 14-pound welder can’t be hard to transport.

Other features: dual voltage (120/240V), can run .023, .030, and .035 MIG and flux cord wire

Another affordable welder that makes almost no sacrifices when it comes to functionality is the Weldpro Mig155GD. A 155A output is one highlight buyers get. Also, 30%@155A duty cycle is expected.

You may be impressed by the 120V/240V dual voltage capacity if you think it can be useful. Also noteworthy is the MIG, flux core, and DC Stick welding capacities in the machine.

The wire sizes fed into the weld, whether you are doing flux cord or MIG welding, are the same. Your three options are 0.023, 0.030, and 0.035 wires.

You can also add TIG welding to the machine if you want. However, the accessories needed for that are exempt from the original package and require you to purchase them separately. Nevertheless, if you so badly need TIG welding in your setup, you might not mind the extra cost as much.

Seemingly, the welder is designed for easy use. Further, drive rollers, flux core wire, and a gas regulator included in the package can help you get started on your first few welding jobs.

What we liked: You can use this welder for DC stick, MIG, and flux core welding. What’s more, if you’re willing to spend extra, you can add TIG functionality as well. The machine’s purchase won’t hurt your pockets as much as some other options. You are provided with a few consumable and non-consumable accessories to work with. Dual voltage capability is something that makes the welder more versatile.

What could be better: For some welders, a maximum welding capacity of 1/8” with regard to material thickness is a letdown.

Welding requires the right tools to cater to the size of your projects. While 120V welders are mostly excellent for home and occasional use, they might not fit the bill for large professional projects. The thickness that 120V welders can handle is also relatively limited. Consequently, these welders would work out in the hands of a home or hobby user. Some of the welders listed above are dual voltage options and thus may have different capabilities.

Qualifying a welder as the best in class for your needs is another step in the process. Here you see the welder’s features and work out whether they would be a fit for your use needs or not. If not, the product is eliminated from your list of options. All welder features are listed below. Your job is to pick those that matter most to you and look for them in potential machine purchases.

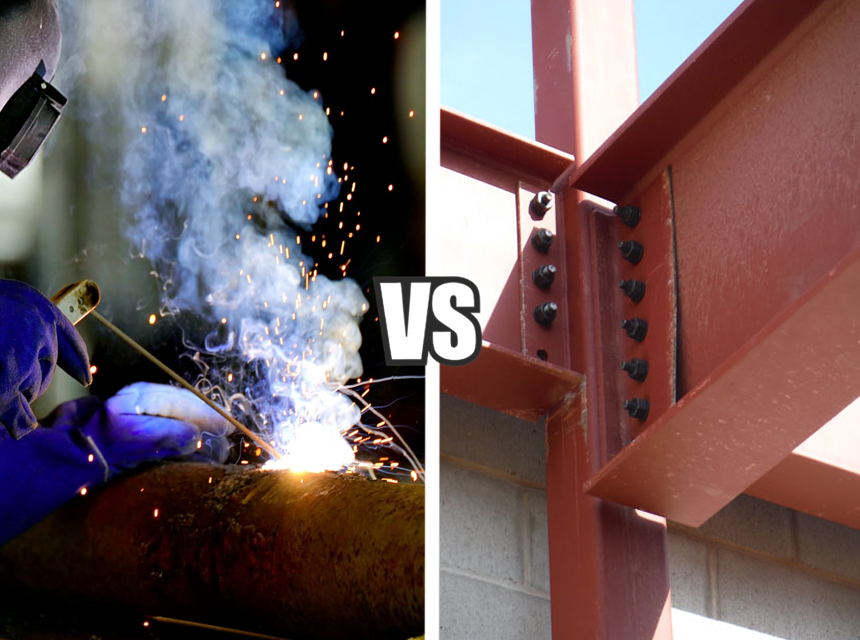

Welding processes listed are essential when looking for the best welder. This is because these processes have varying pros and cons. The welding process options available are MIG, TIG, Stick, and Flux-cored welding.

The Hobart Handler 210 MVP, for instance, only features MIG welding and that will heavily impact how it can be used. As such, we need to delve deeper into these processes so you can have a better handle on them.

MIG(Metal Inert Gas) welding is going to start us off. In cases where you’re welding thick metals together, this might be a good bet. A feed wire is provided and fed to the gun that is doing the welding.

The purpose of the wire is both to ignite a spark and to melt. After melting, it forms the welded joint and is then capable of holding the two metal pieces together. Also, MIG welding may be preferable since it can attach two different types of metals.

Another reason to consider MIG welding is that metal pieces don’t need to be heated all the way through for the weld to be effective. The biggest downside is the need for a controlled environment when MIG welding. Even the slightest wind can be detrimental to the quality of the Weld.

MIG welders can thus be incompatible with the outdoors. If a vertical or worse still, an overhead welding scenario comes up, you will also need to abandon MIG welding. It will be harder to control the filler derived from the feed wire in these scenarios. This might also cause injury.

MIG welding can also burn through some metals if they are thin enough.

Next, we have TIG (Tungsten Inert Gas) welding. Unlike MIG welding, the TIG option doesn’t use a consumable electrode. Instead, a filler metal is added to the welding process by hand.

Contamination of the weld by atmospheric gases is eliminated in TIG welding. This is because either argon or helium is used to shield the working electrode and the weld area.

Also, the clean welds that are as a result of TIG processes are impressive. You get to avoid fumes, slag and spatter from the weld. Additionally, welding in any position should be a piece of cake, including vertically and overhead.

Penetration in TIG welding doesn’t seem all that good. As such, avoid TIG welding the thickest metal sheets you come across.

The mechanisms for flux core welding are quite similar to MIG. They both employ feed wires that act as the electrode in addition to their other job of being a filler. In flux core welding, however, the construction of the feed wire is different. A solid exterior is complimented by shielding flux on the interior.

The flux is generally more effective at shielding the welding arc from any atmospheric gases as compared to inert gases used for MIG welds. As such, welding corroded and painted metals should be easy, even outdoors.

Spattering and smoking is a characteristic of flux-cored welding. The spattering can reduce overall transfer efficiency. This results in more flux-core wire being used. However, this welding process still manages top penetration levels.

Stick welding may also prove a valuable alternative. Like flux core, rusty and painted metals will be light work for a Stick welding machine.

The performance of Stick welders where thin metals that are less than 1/8” are concerned is wanting. The welder will burn right through. Nonetheless, the ability to easily tackle thicker metals may be worth it.

The type of power source your welder is compatible with also matters. AC compatible 120v arc welders will easily derive power from an alternating current power source. In other words, connecting it to a home socket is enough.

Other 120 volt welders like the Lincoln Electric Square Wave TIG 200 have AC/DC capability. This makes them usable in the absence of an AC current. You just pull out a battery with enough power and take advantage of the direct current capability to keep welding.

The power in the welding machine is critical in determining jobs you can tackle. After all, the penetration of the weld is determined by output. As such, the thicker the metals you work with, the higher the output you should pick.

Most welders are not the types of machines to work continuously. However, how long they work as well as break times needed to get back to full working conditions differ from welder to welder. These statistics are known as the duty cycle.

With a heavy welding workload, a shorter duty cycle might be detrimental to your work process. However, short duty cycles may not be as bad where hobbyists are concerned.

Easy transportability is an asset to some welders. If you take off-site jobs, this can be especially true for you. Consequently, a welder like the Forney 291 Easy Weld 180 ST that weighs 14 pounds won’t be problematic to move around. In contrast, the Hobart Handler 210 MVP, which weighs a few times that weight, may be more challenging.

Notably, the wire/electrode diameter is also influential in welding work. You have options such as .023, .030, and .035 diameter wires in the Weldpro Mig155GD device.

A rule of thumb is that a thicker wire will lead to higher amperage and better penetration. This is necessary where thick metal plates are involved. However, you can choose thinner wire diameters if you want to limit amperage while welding.

No one wants to make their welding jobs harder. However, a difficult-to-use interface will definitely lead to that result. Nevertheless, a look at the controls included may be enough to save you from getting a challenging welder.

Welders with fewer, more straightforward controls are a better pick. Once you take out the welder for your first job, you can operate it almost intuitively. Additionally, mistakes are less likely.

A long-lasting welder needs to, of course, be made up of high-quality materials. The exterior especially can be problematic if it isn’t solid enough.

Remember that some delicate components will no doubt be part of the welder’s interior. Consequently, a metal case: with the one on the Forney 291 Easy Weld 180 ST as an example, will help protect the welder’s innards better. With such protection for all significant components, the welder will likely serve you for longer.

A 6-month guarantee from the Forney Easy Weld 140 MP’s maker is the welder’s most underwhelming quality. In comparison, the Everlast PowerArc 140ST’s five-year warranty leaves it in the dust. Of course, welding machine users who want to feel more secure about the purchase will pick the Everlast or another option with a better warranty.

As per our 120V welder options selection, the Hobart Handler 210 MVP, Lincoln Electric Square Wave TIG 200, and Forney Easy Weld 140 MP are our top picks.

The Hobart is a fantastic welder, especially if you have a controlled environment to work in. The metals that you choose to work with also need to be free of paint, rust and other impurities. However, if your work fulfills these conditions, the results of your welding activities are bound to impress you.

As for the Lincoln Electric, superior control over amperage, the pulse feature and easy-to-use interface would make it a fan favorite for anyone trying to tackle TIG and stick welding.

Lastly, the Forney Easy Weld is an awe-inspiring jack-of-all-trades. No matter which welding process you want to use this welder will deliver. Feel free to tell us how you feel about all 120V welders we listed in the comments section below. You can also add a few suggestions on other welders that should have made it onto the list and the reasons why.