Steel has always been one of the more popular welding materials in the market since it’s so easy to work with. However, the same cannot be said of cast iron. It’s a lot more brittle and harder to work with, and hence welders typically avoid using it altogether. That said, welding cast iron to steel or other sheets of cast iron is not impossible. It just requires more technical knowledge and skill compared to average welding projects.

Nevertheless, it’s something that can easily go wrong even with the right skillset. If this isn’t enough to put you off from attempting it, here are some pointers on how to pull it off.

That said, according to Pediaa Trusted Source Difference Between Cast Iron and Steel What is the difference between Cast Iron and Steel? Cast Iron breaks easily, and it cracks at the point of impurities. Steel doesn’t break that easily… pediaa.com , the main difference is the carbon content included in each. The percentage for steel is between 0.05% and 1.7%. As for cast iron, the carbon content stands at between 1.7%-4%. Consequently, there are differences in weldability, shrinkage rate, melting points, castability, and all these aspects make it more difficult to weld the two materials together.

Also, there are more impurities to worry about in cast iron than there are in steel. That said, not all steel is the same, and the same can be said of cast iron. Both steel and cast iron are further divided into multiple subcategories based on the carbon content.

For instance, there is low carbon/mild steel, medium-carbon steel, high-carbon steel, and ultra-high carbon steel. The percentages for all these are 0.05%-0.30, 0.30%-0.50%, 0.50%-0.90%, and finally 0.90%-1.70% respectively.

Typically, higher carbon content in steel makes it more problematic it is to weld. That’s why mild steel is one of the easiest metals to weld. On the opposite end of the spectrum, ultra-high carbon steel is rarely ever welded and is instead used to make hardened tools.

Cast irons also fall into four categories: Gray iron, white iron, ductile iron, and finally malleable iron. If you’re welding mild steel to cast iron, it’s best to avoid using white iron at any cost because it’s unweldable. The same is true for any other high-alloyed cast iron you encounter.

Gray iron, ductile iron, and malleable iron are all weldable. However, they have different attributes, meaning welding these cast irons to steel will be slightly different. According to Science Direct Trusted Source Grey Cast Iron - an overview | ScienceDirect Topics Grey cast iron, or grey iron, has graphitic flakes which deflect a passing crack and initiate countless new cracks as the material breaks. www.sciencedirect.com , Gray iron is brittle with minimal ductility. Ductile iron is cast iron with added elements, e.g., magnesium, that make it a lot more pliable.

As for malleable iron, it starts off as white iron, but with heat treatment, it ends up more ductile. Notably, there’s also the element of expansion and contraction where heating and cooling are concerned. Cast iron expands differently in response to heat compared to steel, therefore, complicating the welding process even further. Lastly, steel tends to have a higher melting point compared to cast iron.

Ultimately, how you weld cast iron to steel will depend on the equipment you have, but it is possible. Of course, you have various welding processes to choose from. Nonetheless, some will make your work easier and cheaper than others, and we look at these options below.

Users recommend the SUNGOLDPOWER 220/110V Stick welder for such a welding project since it offers digital control, which may be essential for the success of your welding project. As mentioned in the name, it also works with both 220V and 110V outlets. Lastly, there are multiple welding rods for cast iron to mild steel projects available in the market.

You’ll also need nickel wire that’s made explicitly for cast iron. However, this wire doesn’t come cheap. Lastly, you’ll have to use the short-circuit transfer mode, which will ensure low heat input, and consequently, there won’t be much expansion and contraction on the cast iron side.

As for the process, here’s exactly how to weld cast iron to steel.

This is where you organize your equipment and working materials. As mentioned above, there are multiple types of steel, including mild, medium, and high-carbon steel, that you can work with. As such, you first need to know the kind of steel in your hands. Of course, if you want an easier time welding, you should plan to use mild steel.

With regard to the cast iron, ensure you’re using either gray, ductile, or malleable iron. Also, you can use Stick, TIG, and even MIG welding, so you’ll need to decide based on the welding machine you have in your possession. If it’s gray iron, you’ll need to preheat the metal before welding and ensure the cooling is much slower.

If it’s malleable iron, you’ll need to factor in heat treatment in the welding process; otherwise, it will lose its ductility in the area next to the welded joint. However, you needn’t worry as much about cracking as you would with the gray iron. Lastly, if you have ductile iron losing the ductility in the heat-affected zone next to the weld area after your project is guaranteed. That said, it also doesn’t crack easily.

Nevertheless, we recommend gray iron since it’s much more common.

You also need to ensure the impurities inside the cast iron don’t cause problems later on. After all, they can get into your weld puddles and cause porosity. Of course, this will lead to less structural and thermal strength in the weld area. As such, it’s best to clean the weld joints beforehand.

Use an angle grinder to clean at least 1” of space next to the joint area on the cast iron. You can also use it to clean the steel. Eliminate any remaining carbon on the surface of the metal by filing it down. Notably, oil may also be one of the impurities you encounter in your cast iron. In such a case preheating the metal with a flame torch should be enough to get rid of it.

Alternatively, a non-chlorinated degreaser will make light work of the oil as well. For TIG welding, you’ll also need to eliminate the flux covering on the filler rod.

Bevel the Joints

Bevel the JointsSince you’ll likely use nickel filler material, it’s best to bevel the edge of the metals to 35°. When melted, the filler material is highly viscous and won’t flow as easily into the joint. The 35° bevel is therefore meant to help with penetration.

Die and angle grinders work well for the job; however, they have issues. For instance the die grinder, you have to use carbide burrs, and there’s bound to be flying debris. Consequently, it’s advisable to wear protective gloves and a mask before you get to work. Users recommend the YESWELDER LYG-M800H welding mask because it provides a large viewing area for your workpiece. It’s also comfortable to wear for longer periods.

As for the gloves, reviewers insist on the RAPICCA option, which is made of leather and is double-reinforced to protect your hands.

The angle grinder imparts too much heat on the workpiece due to friction, and it’s better to take frequent breaks as you bevel. A hammer and chisel may require more effort on your part, but there’s not much flying debris or friction to deal with.

Preheat the Cast Iron to the Right Temperature

Preheat the Cast Iron to the Right TemperatureUse a flame torch to raise the temperature of the gray iron to 500 °F. Using an oven will get you similar results. Also, once the ideal temperature is achieved, you have to keep it stagnant or as close to the 500 °F temperature as possible throughout the welding period. In some cases, this might require reheating the metal.

Start Welding

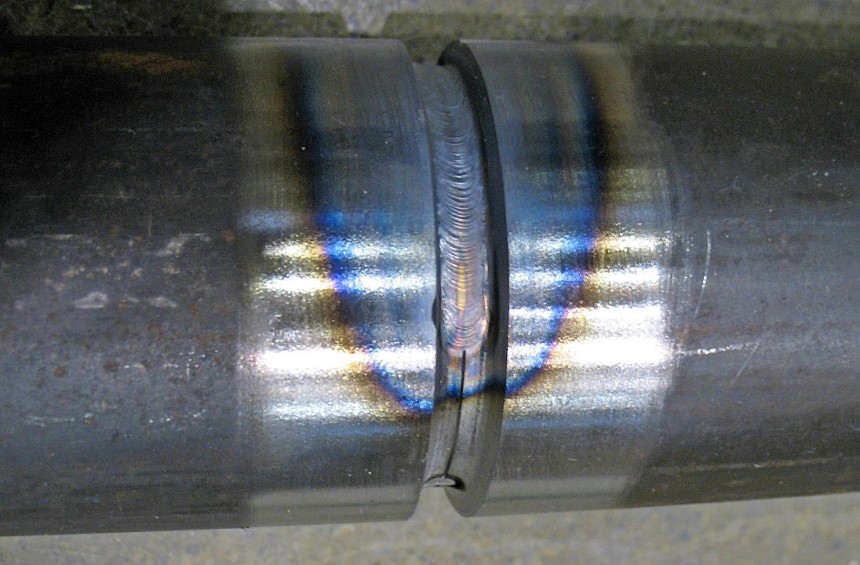

Start WeldingNotably, welding these two distinct metals isn’t as simple as putting together two steel sheets. Instead, you’ll weld smaller 1” beads before moving to a different part of the joint to repeat the same thing. Also, ensure a better connection by placing the clamp as close to the joint as possible.

Next, remember you don’t want the temperature in one area to rise too fast as it may lead to cracking during the cooling stage. As such, there are a couple of steps to prevent this.

First, you have to stagger the bead placement on the joint while using the lowest amperage possible. Additionally, you have to maintain a fast travel speed for the same reasons. Avoid waving the welding tip as well. Next, ensure you fill the crater with the filler metal. Finally, you have to start the beads either on a previous bead or in the middle of the joint.

Notably, even with all these steps, cracks might still appear. If so, you’ll need to halt their progression by drilling holes at their ends, cleaning the cracks, and then welding them together using the same process described here.

Ensure the Structural Stability of the Weld

Ensure the Structural Stability of the WeldBeat the beads into the joint repeatedly using a rounded hammer. This will keep the steel from exerting too much mechanical pressure on the cast iron as it shrinks, therefore, preventing cracking. Follow up closely by reheating the cast iron side of the joint to the 500°F temperature and then ensure the metals and joint cool as slowly as possible.

You can do this by using an insulation material that won’t burn from the heat. Fiberglass is a good example. Once it’s done cooling, the weld should be complete.

Final Thoughts

Final ThoughtsWhile welding cast iron to steel is a long and tedious process, it typically doesn’t form the strongest joints. As such, you should avoid it when you need higher structural and thermal strength. However, if it’s for something decorative, it’s not a bad idea to attempt it. Also, it’s not something that most home welders can do, so you might bag yourself some bragging rights once you get proficient at doing it.