Not all metals are welded in a similar manner or with the same welding materials. Chromoly, an alloy steel strengthened with chromium and molybdenum, is welded differently than other standard alloys. It is also known as 4130 steel which basically is a code that defines its chemical composition. It offers the perfect combination of strength, ductility, and weight and is thus suitable for aviation and motorsports projects which require less weight but a lot of strength.

Welding Chromoly requires a lot of preparation and enough technical know-how. This article has all the pointers to help you weld the alloy properly, whether you are a beginner welder or a pro. Before you learn how to weld, you must first understand the properties of the metal alloy well.

Chromoly is a metal alloy that constitutes the metals chromium and molybdenum. The American Iron and Steel Institute assigned the alloy a code to define its chemical composition. The code is 4130 and 41 indicates that Chromoly is a low alloy steel that has Chromium and Molybdenum as its main components. The number 30 indicated 0.30% of carbon content. The chromium content in Chromoly is usually anything between 0.8 to 1.1% and Molybdenum anything between 0.15 and 0.25%.

Chromoly Properties

Chromoly PropertiesHere is an in-depth exploration of the physical and mechanical properties of Chromoly:

Chromoly or 4130 is considered a low-carbon steel, and it has a density of 0.284 pounds per cubic inch. The alloy benefits from heat-treatment hardening and is an exceptional welding steel that can be welded with virtually all commercial methods. The alloy is also readily machined in its normalized or tempered condition.

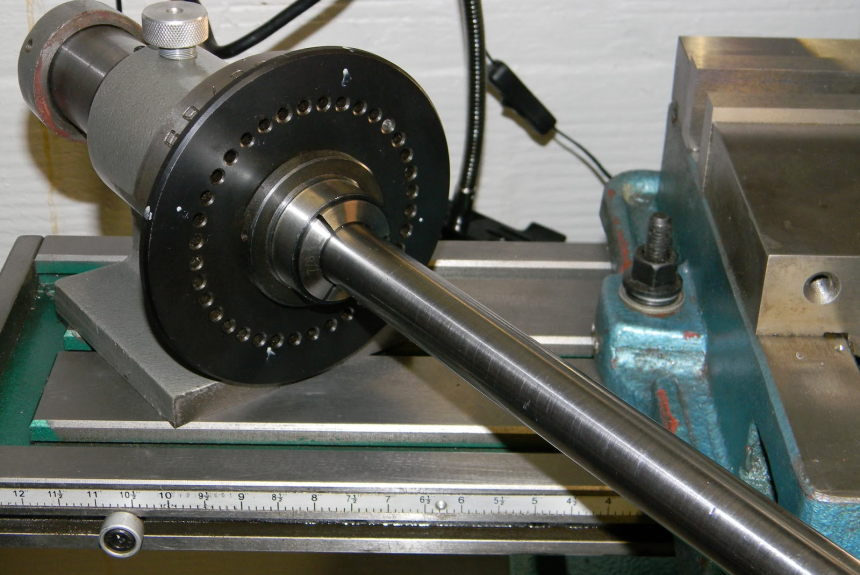

You can easily cold work, hot work, or forge Chromoly, but you cannot age it. Its ductility is exceptional when annealed, making it the ultimate structural steel. Chromoly mostly comes as a round tube or bar stock in structural applications.

Chromoly has a high modulus of elasticity. This means it can bend easily and withstand large stresses but still manage to return to its original form. This is one of the properties that make it a perfect structural steel because it can remain rigidly in place.

Further, the alloy has a relatively lower tensile yield strength than other steels, but it is much better than most aluminum alloys. Tensile yield strength determines the amount of stress a material can withstand before it has any permanent changes in its geometry.

When it comes to hardness, Chromoly shines. It has a high Rockwell hardness which makes it incredibly stiff and ideal for compression. What’s more, the alloy is also high in elongation, which is the measurement for how bendable it is or its ability to withstand plastic deformation. The high elongation means the alloy steel has great workability.

Welding Chromoly is somewhat different and a bit difficult than welding other metal alloys. You can use either TIG or MIG welding Trusted Source MIG vs TIG | Welding Types, Materials, and Applications - A Guide A comparison between MIG and TIG welding, outlining what the processes entail, advantages, materials utilized, and typical industrial applications. www.technoxmachine.com to work Chromoly. The following tips and tricks will help you weld the alloy like a pro, even if you have little experience.

Preparation

Here are some of the preparation steps you must finish before proceeding to the welding process:

Tube Preparation

Choosing a Torch Setup

Go for a torch setup that suits the welding application you’ll be using. The weight and mobility of the welding torch will affect its ease of use, convenience, and productivity. For efficient welding of Chromoly, go for a high-quality TIG welder. Also, consider getting a gas lens with a larger diameter, as it will form a larger gas shield that will give you an easier time when welding.

The Weldpro Digital TIG 200GD is one of the most acclaimed TIG welders on the market. It is incredibly easy to use this perfect for both beginners and professional welders. It also offers excellent versatility with its MMA stick welding function.

If you choose to MIG weld, consider the popular Hobart 500559 Handler MIG welder. It is a versatile option with MIG and Flux-cored welding capabilities. Thanks to its 5-position voltage control selector, you’ll enjoy a smooth, stable arc at all welding thicknesses.

Choosing Filler Materials

There are 3 filler materials best suited for welding Chromoly: ER80S-D2, ER70S-2, and 4130. The ER80S-D2 and ER70S-2 are the most popular options because they have a high tensile strength that is pretty close to that of Chromoly itself. 4130 matches the material to be welded, but you cannot use it with a thin-wall tube.

You can use the ER70S-2 for projects that don’t require the filler material to match the strength of the Chromoly. Although the weld won’t match the strength of the Chromoly base metal it will offer great crack resistance.

The ER80S-D2 is ideal for projects that require a filler material of equal strength to the Chromoly base metal. When the Chromoly steel structure is in an annealed state and is not supposed to be subjected to post-welding heating, a filler with matching strength must be used. Annealing removes internal stresses to make it tougher. The filler material must also be annealed to increase its strength leading to a robust, durable weld that isn’t prone to cracking.

If the Chromoly steel must be hardened post-welding, then you have to use a filler material with the same strength and chemistry like 4130. The only downside to using 4130 is that its high levels of carbon make the weld prone to cracking.

Welding Process Step-by-Step

Chromoly’s welding process is a bit different from that of other metals. There are a few things that you must consider to ensure the weld is strong, durable and smooth. Here is a step by step guide on how to hack the welding process of Chromoly like a pro;

Step 1. Pre-heating Chromoly

If the Chromoly tubing is thicker than 0.12 inches pre-heat it at a temperature of 300 to 400 degrees F. If the tubing is thinner, you don’t have to preheat it. You can easily do this with a small propane torch like the one at Home Depot.

Step 2. Use a Lift Arc

Instead of a scratch start, use a lift arc as it is more stable. A lift arc is pretty simple, all you have to do is torch the tungsten to the base Chromoly metal, start the pedal, lift the welder, and start welding. Only a TIG machine with high frequency starting can eliminate the arc strikes which cause brittle spots that make your weld prone to cracking.

Step 3. Slope In and Out Slowly

According to experts Trusted Source Structural analysis of TIG generated chromoly welds This work presents the results of investigation on the material characterization of a TIG-welded A-4130 Chromoly steel. www.ijser.org , you should slope in and out gradually because Chromoly is very temperamental. If you do it rapidly, you may make it brittle. Keep the tungsten close to the metal to ensure the arc cone is narrower. Also, taper off amperage slowly to prevent any crater holes from developing and turning into cracks later on.

Step 4. Cool the Weld

Avoid cooling the weld rapidly. This can cause the weld to crack. Ensure no breeze is entering the welding room and drying is only occurring naturally.

There’s no harm in preheating your Chromoly tubing before welding, but you don’t have to do it, especially if the tubing is thinner than 0.12 inches. If it is thicker than 0.12 inches you should preheat for better weld results.

Chromoly is a very strong metal alloy and is often used in the manufacturing industry to achieve a lighter but stronger structure. It is stronger than steel as it has greater tensile strength, but most of the time it’s the thickness of the metal being used that makes a difference.

Chromoly is assumed to be lightweight because structures made from it weigh less than structures made from other metals. The structures weigh less because less material is used as Chromoly has incredible strength. So, NO! Chromoly is not lighter than steel.

Chromoly is a special steel alloy that offers a great balance of strength, ductility and lightness. It is a perfect structural steel for projects that require less weight but more robustness and ductility like the car racing, motorbiking and aviation industries. The metal alloy has special properties which make welding it a bit more complicated than other metals. You need proper preparation and skills to hack the welding process.

We have provided all the hints and tips on welding Chromoly. You can choose to MIG or TIG weld. A high quality TIG or MIG welder will make all the difference. You must also ensure you get the correct filler material for a high-quality and long-lasting weld.