If you enjoy engaging in small welding projects for home improvement or are a small business that deals with metalwork repairs and auto body repair works, you’re probably having a hard time choosing a welding machine that will suit you best. There are 2 integral features that you need: a machine that you can easily plug into a standard power source and is also reasonably priced. Some light research will quickly reveal that the Hobart 140 and the Lincoln 140 are your 2 best options. Both brands are a household name among the welding community and are known for manufacturing high-quality welding machines. If you’re having a hard time choosing between the two, we have compiled this Hobart 140 vs. Lincoln 140 review to make it easy for you. Their specifications and features are surprisingly similar but depending on your intended use; one might be a better fit for you than the other. Which one should you go for? Keep reading to find out!

The Hobart 140 and Lincoln 140 are both great 140 amp models and are mainly preferred by welders that need a machine for light to medium-duty applications, including domestic repairs. Even though they are mostly bought by welders in the starter and intermediate categories, it’s not uncommon for professional welders to buy them due to their efficiency and portability.

Both the Hobart 140 and Lincoln 140 are also highly affordable. Even though they have some limitations, they are a great buy and are equipped with the basic functionalities to handle small-scale jobs. We’ve started off with an in-depth review of each welding machine to give you insights into their features, reliability & functionality. We’ve also compiled a comprehensive guide of their main differences to help you identify the welding machine that best suits your needs. Let’s dive in!

| Hobart Handler 140 | Lincoln Easy MIG 140 | |

| Process | MIG, Flux Core | MIG, Flux Core |

| Input Voltage | 110V/115V/120V (20A) | 110V/115V/120V (20A) |

| Amperage | 25 – 140A | 30 – 140A |

| Duty Cycle | 20% @ 90A(18.5V) | 20% @ 90A(19.5V) |

| Voltage Control | 5 Fixed Positions | 4 Fixed Positions |

| Weldable Metals | Mild steel, Stainless steel, Aluminum | Mild steel, Stainless steel, Aluminum |

| Wire Feed Control | Infinite | Infinite |

| Wire Feed Speed | 40 IPM – 700 IPM | 50 IPM – 500 IPM |

| Wire Spool Size | 4-in. & 8-in. | 4-in. & 8-in. |

| Material Thickness | 24 ga – 5/16 in. (mild steel) | 1/4 in. – 3/8 in. (mild steel) |

| Wire Thickness | .024 – .035 in. | .025 – .035 in |

| Dimensions | 12.4 x 10.6 x 19.5 in. | 13.7 x 10.1 x 17.9 in. |

| Weight | 57 lbs. | 62 lbs. |

| Warranty | 5/3/1 years | 3 years |

There’s something satisfying about being a DIY-er. You get to take on projects that you enjoy around your home and still save money while at it! This is the true definition of a win-win situation. According to Forbes Trusted Source DIY Vs. Pro -- Who's Doing What At Home? The ranks of do-it-yourselfers seem to be growing, but not for every category. The Home Improvement Research Institute reports that two thirds of projects are completely DIY today, with interior painting and landscaping leading the way for homeowners going it alone. www.forbes.com , more people are embracing DIY household projects, and in 2018, a quarter of the entire population did their home improvements. Of this number, only 7% sought professional advice to help with project completion.

The Hobart Handler 140 is perfect for small-scale activities such as plumbing, fixing exhaust pipes, and generally any small repairs around your home.

In addition to the impressive build quality, the Hobart Handler 140 is versatile, lightweight, and performs like a beast. It’s also portable and is a great option for first-timers who need a welding machine for light outdoor projects. One of the features that make it invaluable to beginners is the ability to switch between various wire speeds and different volts, allowing you to improve your welding skills.

Its key features include:

Overall, whether you’re a DIY enthusiast looking to make your first welder purchase or are a pro looking for a great machine for lightweight jobs, the Hobart 140 should be at the top of your list. This is especially true if your activities are limited to mild and small-scale welding.

We enjoyed how easy the setup process was. The Hobart 140 kit came with:

Anyone that has used Lincoln welding machines knows how dependable they are, and the Easy MIG 140 model is no different. It’s backed by a solid heritage and a major global presence. This welding machine is popular among small businesses and home enthusiasts, and it’s not hard to see why. It’s very easy to use, especially with sheet metal, and is highly versatile.

This 140-amp entry-level welding machine is great for domestic projects on light steel and aluminum sheets.

Even though this machine seems small, it’s not lightweight and weighs around 71lbs. Lincoln is known for manufacturing welding machines with an ergonomic design, and the Lincoln Easy MIG 140 has 2 driver’s wheels. Both of them are made of metal, and one is lower, and the other one is upper. You can easily switch between various diameters, thanks to the 2-piece wire guides. Even though some people may find the cable short, it should work perfectly in small garage setups and in most homes and gardens.

The key features of the Lincoln Easy MIG 140 include:

The Lincoln Easy MIG 140 b0ox comes with:

The Hobart Handler 140 and the Lincoln Easy MIG 140 welding machines are 2 of the best entry-level models in the market. Both are made by reputable manufacturers, and from their overviews, it’s clear that they have distinct differences. Here’s how they both compare.

Both the Hobart Handler 140 and the Lincoln Easy MIG 140 support MIG and Flux core welding.

Flux core welding is great when you’re dealing with thick joints because it has great penetration capabilities. You can also hold the torch and travel in various directions, which is why this type of welding is best suited for general repairs. MIG (metal inert gas) welding, on the other hand, works best when used on thick and large materials. It’s a faster process, and the availability of inert gaseous such as carbon dioxide has made it popular, especially for steel welding. MIG welding is also cheaper.

Both welding machines can run on low power output, but their voltage positions are different. The Hobart 140 has a 5-position voltage dial, while the Lincoln 140 has 4 voltage positions. This makes the Hobart 140 perfect for finding the ideal heat setting.

The Lincoln model only runs on 120V, while the Hobart 140 can run on either 110V, 115V, or 120V. The base current sources in your home are, however, enough for both welding machines.

Since both machines come with tapped dials, fine-tuning the voltage settings is difficult. This should, however, not be a point of concern as these welding machines are designed for beginners, and tapped switches are easier to use.

When it comes to aluminum welding, the Lincoln Easy MIG 140 is a better option as you can buy a spool gun to add this functionality. The Hobart 140, on the other hand, requires significant adjustments, such as putting a Teflon liner in the hose of the MIG gun.

Since both machines have a 140-amp maximum output, they are incapable of welding mild steel in large quantities or thick steel.

Both machines can weld on Aluminum, stainless steel, and steel. The Hobart 140 can weld materials with a thickness of ¼ inches, while you can weld up to 3/16 inches with the Lincoln machine, giving it a clear advantage.

The Hobart 140 and Lincoln Easy MIG 140 tie when it comes to amperage. Both machines have a similar output power and have a maximum amperage of 140. They are designed for use in a standard American household with 20 amp circuits and 120v. The output amp of the Lincoln ranges from 30-140 amp output while that of the Hobart 140 is 24-140 amp. This is a very small margin of difference, and it doesn’t make much of a difference.

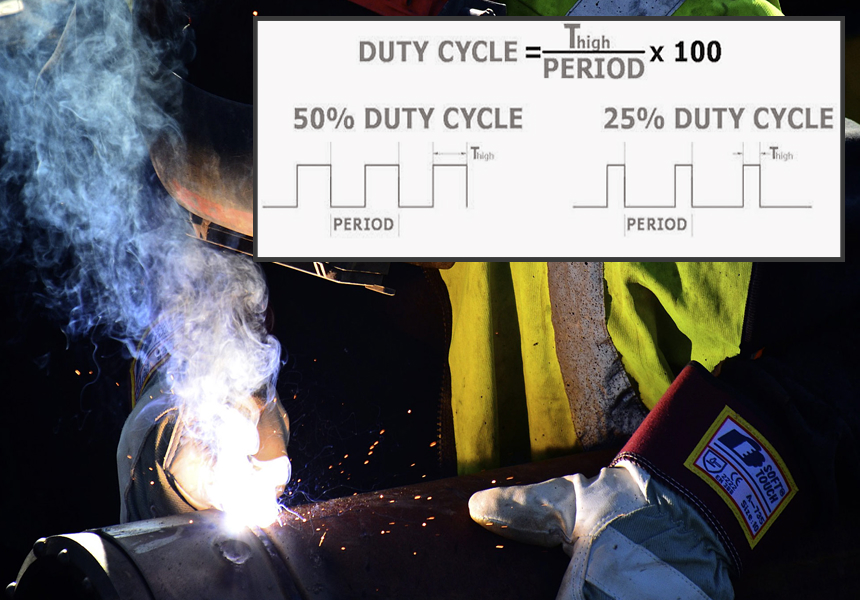

If you’re just starting your welding journey and don’t know what a duty cycle is, we’ll explain it briefly for you. This is the time it takes for you to weld before your machine begins to overheat within a 10-minute time frame. Both machines have a duty cycle rate of 20% @90 amps. Theoretically, this would mean that in 10 minutes, you can weld for 2 minutes and then let the machine cool off for 8 minutes. However, in practice, the cooling period is around 15 minutes. This is because this time is also dependent on the amp setting that you were using and the current environmental temperature.

Generally, welding machines that have a low amp tend to have higher duty cycles. In this round, both machines are equal.

Both Hobart 140 and Lincoln 140 machines allow for a quick and easy start since they come with sample flux-core wires. Both models have a wire feed drive system that uses .030-.035” wires for flux-core welding. If you’re working with aluminum sheets, you can use a .030” aluminum wire.

Even though both welding machines are low-budget, entry-level models, the manufacturers equipped them with all-metal wire feed drive rollers. This is impressive because most of the other models use cheap plastics, which are less durable. The Hobart 140 and Lincoln 140 also have adapters that allow you to switch between 10 pounds and 2 pounds spools of wire.

There’s, however, a major difference between the 2 models for those who plan on buying them to mainly weld mild steel or steel. The Lincoln 140 can fit .025-.035 inches. Solid wires, while the Hobert 140 offers a range of .023- .035 inches. When it comes to welding thin materials, wires with small diameters are preferred, which gives the Hobart 140 an upper hand.

The welding controls on both models are fairly straightforward. They have 2 control knobs and a simple on and off toggle feature. One of the knobs is used to control the voltage settings, while the other controls the WFS. You can easily operate these controls even with gloves on, but we noticed that they are a bit small.

The operating panels of the Hobart 140 and the Lincoln 140 are almost similar, and the only difference is in their orientation. The 2 dials are side by side or horizontal on the Lincoln 140 but are vertically stacked on the Hobart 140.

Both units are fairly easy to use and have been designed with first-time welders in mind. The control panel design is simple and has a clear view. You can also adjust the voltages and wire feed speeds with ease, thanks to the control knobs. The Hobart 140 and the Lincoln 140 welding machines also allow you to achieve a smooth arc performance with a smooth start.

A welding machine that’s easy to transport is a major advantage as you can use it around your home with ease. Both the Hobart 140 and the Lincoln 140 models are lightweight and portable.

The Hobart is smaller and more lightweight compared to the Lincoln. It measures 12.4 x 10.6 x 19.5 inches and weighs 57 pounds, while the Lincoln 140s dimensions are 13.7 x 10.1 x 17.9 inches and weigh 62 lbs.

When you’re choosing welding machines, thermal protection should be one of your top priorities as it protects you and your device. Both units have output overload and thermal overload protection features. If the set limits are exceeded, the machine automatically goes off and only turns on after it has cooled. The Hobart 140 and the Lincoln 140 also have cooling fans that help maintain optimal temperatures during welding.

Both units have work cables that are easy to handle and 10-foot MIG guns that are comfortable to use. The cables are a heavy 6-gauge, but the Hobart 140 lacks a bonding cable and is smaller. The Lincoln 140 has a work clamp that makes a great circuit.

The Hobart 140 unit has a 5/3/1 warranty which covers labor on the power sources for up to 5 years, 3 years for the control boards, drive system, and regulator, and 1 year on the relays, contactors, and MIG gun. Lincoln 140 only has a 3-year warranty on parts and labor. This excludes the gas regulator, which has a 1-year coverage, and MIG gun, which has 90 days coverage.

Based on the above review, both welding machines have their distinct similarities and differences. They are made by reputable manufacturers, are fairly affordable, and are entry-level units. You should make a choice based on your individual welding needs. For instance, if you’ll be mainly working with aluminum metals, the Lincoln Easy MIG 140 should be your top pick. The Hobart 140, on the other hand, has better warranty coverage and is more lightweight.

According to Harvard.edu Trusted Source Recent Upturn in DIY Remodeling Projects Unlikely to Continue Long-Term | Joint Center for Housing Studies During the pandemic, there has been a surge in do-it-yourself (DIY) home improvement as people have used some of their extra time at home to undertake projects that accommodate changes to their lifestyle. www.jchs.harvard.edu , there has been a significant increase in DIY activities. If you’re thinking of engaging in welding projects around the house, these 2 units are a great option. While there’s no such thing as the perfect entry-level welding machines, this Hobart 140 vs. Lincoln 140 review proves that these 2 models come dangerously close. It’s hard to contest their efficiency, affordability & reliability. They’re also versatile.