The Hobart Ironman 230 Mig Welder has a chosen specialty that you will notice the moment you start to weld with it: It offers control. Not control in terms of the most agile mobility of the welding stick, but control in terms of the least unpredictable things happening during the weld.

No one likes to admit it, but welding is a chaotic process. You can have the most steady hand in the world, apply your purifying gas perfectly, set your parameters up exactly, and still, the spatter and imperfections in the materials you are working on can cause mishaps. In this Hobart Ironman 230 Mig Welder review, the main question that needs to be examined is what, exactly, makes this welder so accurate.

MIG welders are known for their accuracy, as rather than haphazardly placing their filler material on their parent and weld metals, they feed it into the weld through a loop of material. Even this trait cannot protect them from the natural dangers of welding, though.

The imperfections that cause perfect hands to make imperfect welds are imperceptible to the human eye. No one, no matter how skilled, can avoid them. But what if you did not have to worry about them? How can a welding tool solve this problem that its welder cannot?

The Hobart Ironman 230 Mig Welder solves this problem by optimizing its arc. The arc has a twelve-tap voltage control that allows you to deliver exactly the amperage you need.

If you are burning your metal, you have the accuracy in turning it down, and if you are getting spatter, you can turn it up. Many welding tools have this, but none have as many options.

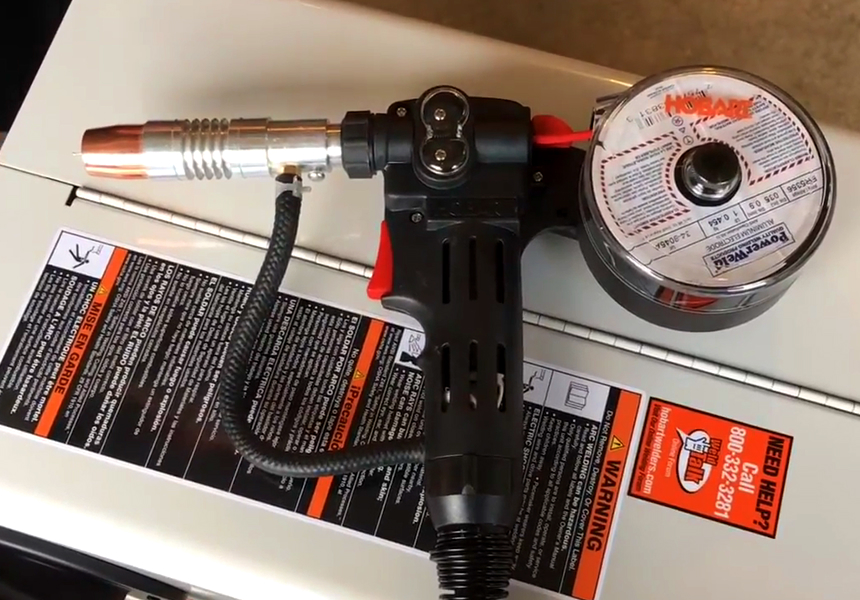

The Hobart Ironman 230 is a perfect welder, providing clean lines and easy control. The power it outputs makes welding feel fluid and simple, while its tools for adjusting parameters are easy to understand. It is also maneuverable, coming with a ten-foot spool gun.

It is a Mig welder, meaning you will have to provide your own filler materials for it, as well as a purifying agent. Its efficiency in welding makes sure that your materials do not go to waste.

MIG welding is one of the preferred ways of welding not because it is simple, easy, or efficient—it requires you to know how to set it up, know how to operate it, and actually costs materials to do it. No,

MIG welding

Trusted Source

How is Argon Used in MIG Welding and how do MIG and MAG Welding Differ? | CWB Group

The acronyms MIG (Metal Inert Gas), MAG (Metal Active Gas) and GMAW (Gas Metal Arc welding) all describe the same basic welding process. In this welding process, an arc is struck between a continuously fed consumable electrode and the workpiece as depicted in Figure 1. The consumable electrode is a bare wire. The heat generated by the arc melts the electrode and part of the base metal in the weld area. The arc itself transfers molten metal from the tip of the melting electrode to the workpiece, and here it combines with the melted base metal to form a weld deposit.

www.cwbgroup.org

is preferred by many people because it is versatile.

Everything from 18 gauge metal to two-inch steel can be welded by a Mig welder. Each material requires different parameters for your filler material and gas, but you can go from welding aluminum to stainless steel to titanium without having to change devices.

Almost all materials can be welded below 200 amps, and only the most temperamental materials need more than that to be welded. That means that the welding gun has a huge range that can be as delicate or as intense as you need it to be.

No MIG welder is exactly “easy” to use. No matter what you do, you will always have a few decisions to make about the amperage of your arc, the kind of gas you use, and the density of your filler material. And even beyond those decisions, you have to know how to set them all up.

This Mig welder is one of the easiest to use once you start welding, but there is very little helping you actually get there.

The Hobart Ironman 230 Mig Welder has two kinds of safety features: manual ones and automatic ones. The manual safety features are the dynamic amperage settings that allow you to “undercook” your weld if you are not sure your metal can handle the heat of higher amps.

This also allows you to turn up the amperage and prevent your weld from needing too much post-weld cleanup. The automatic safety Trusted Source Welding Safety Tips and Guidelines for 2020 Accidents happen, but many injuries can be avoided by having an understanding of what to do and what not to do when working in a welding environment. Before starting any project, welders must take the time to ensure they know how to execute the task safely above all else. It’s the most important thing they can do to protect themselves and those around them. www.uti.edu features are the industry standards: tip protectors that protect your contact tips by shutting down the device if its work cycles are overloaded.

The portability of the Hobart Ironman 230 Mig Welder is where it really does not deliver. This device is 224 pounds even when it is not laden with gas and filler. That is double the next largest Mig welder at the same price point.

Maintaining any Mig welder can be tough, but this one helps you out a little. Because of the clean welds that this device can produce, it at least does not have to deal with as much spatter reaching the welding gun. It can wear out quickly if you only use one amperage, though.

This machine puts a lot of strain on itself, and as expected, that means there are a lot of moving parts that can break, resulting in a shorter expected lifespan. However, one of the best parts about Hobart products is that they have notably good warranties.

In fact, some reviews report being sent free replacement parts even outside the warranty period. The device might have issues, but the company is willing to work with you to fix them.

The price of the Hobart Ironman 230 Mig Welder can vary from seller to seller, but it will never be lower than $2000. The reason for that price is that there really is no Mig welder that can do what this device can do. As expected from an irreplaceable machine, it has a high price point.

The main reason you would get this Mig welder over any other is that you know what you are doing and know that you have a lot to do. The versatility in amperage allows you to apply different intensities of welding to all kinds of metals, ensuring accuracy on any job.

| PROS |

CONS |

|

|

The story of the Hobart Ironman 230 is one of the high highs and low lows. There really is no better MIG welder to have on hand if you are a working professional. With it, you can do any job under the sun. But that versatility comes at a steep cost and has a lot that can go wrong with it.

It is not a MIG welder for someone who does not find themselves welding professionally. To boil it down into a sentence, the most accurate Hobart Ironman 230 MIG Welder review would be: “Bad for hobbyists, amazing for professional welders.”