Can you weld aluminum with a gasless MIG welder? TIG welding is also known as MIG welding, which uses shielding gases to provide the best environment for binding aluminum with a clean weld. However, your inert gas may run out before you finish your project, and you may only have a few welds to complete the project. You may be forced to go gasless, and it becomes essential to know about MIG welding aluminum without gas.

Many different products in the market offer you multifunctional aluminum welding capabilities, the most reputable one being the Tooliom 135A MIG welder. To properly weld aluminum, you will be required to find the best TIG welder for aluminum in the market. If you find the right one, you won’t have any problems with welding.

Aluminum can be adequately welded in the absence of gas in a vacuum chamber. It is worth noting that gasless aluminum welding in the open air will fuse the oxygen in the surrounding with the metal forming a weaker weld. This is why structural welding is not a project that you can do without inert gases because of the importance of strength in the structures. However, if you’re doing a tutorial or any light welding project with aluminum, it is safe to do this without gas. Knowing how to adequately put to use all your equipment even when you lack gas is important for any experienced welder.

If you do not require the weld to support any heavyweight, you can go ahead and perform the aluminum weld in the open.

The most common use of gasless welding of aluminum is adding signatures to completed welding projects. It is also ideal in helping create visually appealing designs that will not experience any significant forces. In short, you can always rely on gasless welding of aluminum with MIG for all your cosmetic welding projects.

Now that you know it is possible to weld aluminum without any shielding gas, you cannot wait to start. The best place to begin exploring welding aluminum with MIG without gas is by understanding the terms. MIG stands for Metal Inert Gas Trusted Source How to Weld Aluminum | Universal Technical Institute Aluminum welding requires different techniques and processes than welding steel, and it’s critical to know these differences in order to complete successful welds and work on a variety of different projects. www.uti.edu where is TIG is the acronym standing for Tungsten Inert Gas. The term inert gas in both instances is essential because it expresses how indispensable it is in producing a perfect weld.

There are many MIG welders in the market, with some enjoying more positive user reviews than others. One of the reliable welders you can use is the Super Deal Pro MIG 130 Welder, which users have reported to be powerful, lightweight, and a fantastic invention. There are two ways of welding aluminum with MIG without gases. When using a MIG welder without gas, aluminum oxides will form and contaminate the welded portions. The situation is made worse with bubbles that arise from aluminum’s interaction with other materials in the atmosphere.

However, when the aluminum being welded is not for structural uses, the weld will hold just fine. Below are two ways that you can use to achieve gasless aluminum welding with MIG.

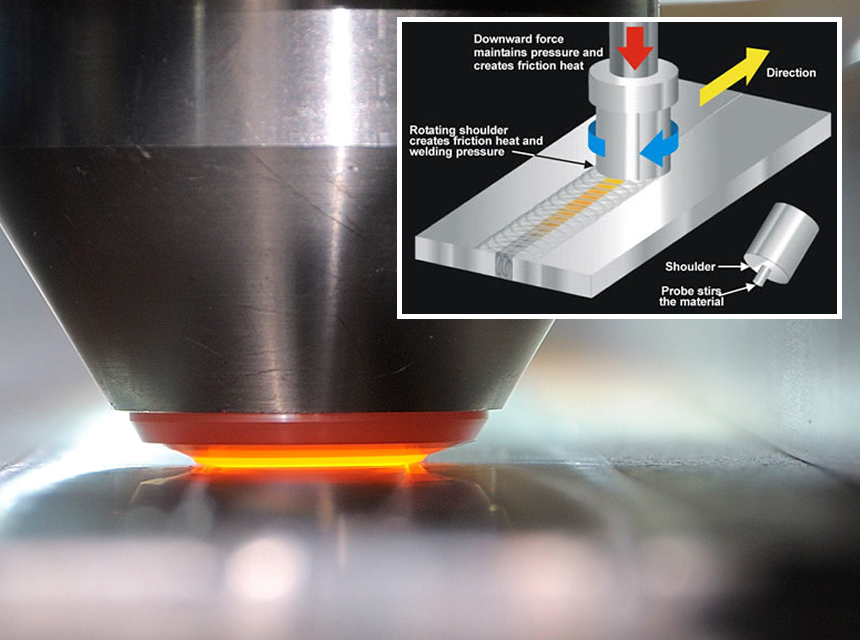

This is among the most relied-upon gasless welding techniques that you can use to weld aluminum effectively. The principle behind this technique is to melt the aluminum pieces and merge them to form one continuous piece. This method of aluminum welding produces perfect results to avoid even X-ray detection. Friction stir welding is quite efficient due to its use in underwater and outer space welding projects.

However, friction stir welding is a highly specialized activity and is not commonly associated with home use. When you want to join aluminum without shielding gas, friction stir welding is one of the most efficient ways of going about it. Many welders continue to incorporate friction stir welding in their home workshop, specifically for gasless aluminum welding with MIG.

The other efficient gasless welding method that you can use when working with aluminum is vacuum chamber welding. This welding technique incorporates a vacuum chamber that sucks out air removing it from the equation entirely. Sucking out the air is a process that is done with a vacuum pump that ensures the environment around the pieces of metal you want to weld is free of any contaminating gas is like oxygen. This means that you do not require shielding gases to come up with a perfect weld when working with aluminum. The only downside of using vacuum chamber welding is that vacuum chambers can be quite costly. You are sure not to find a vacuum chamber in your typical garage, and this method of gasless aluminum welding with MIG is usually applied in industrial settings.

Vacuum chamber welding is very efficient in creating strong and clean welds that can be used for engine parts. Another application of vacuum chamber welding is in the manufacture of high-pressure aluminum air ducts.

Some obstacles are common in aluminum gasless welding with MIG, and it is wise to try and avoid them as much as possible. These include craters, burn-through, improper fusion, and porosity Trusted Source A Review on Defect Minimization in MIG Welding | Dilesh Thakre | Academia.edu In this study, Metal insert gas welding (MIG) is a joining process which is used to many years due to its advantages such as low heat input, higher welding speed and little loss of allowing material. www.academia.edu . Compared to other metals, it is relatively hard to work with aluminum because of its higher thermal conductivity and low melting point. Below are some of the recommended ways of avoiding such circumstances.

This acts to reduce the risk of porosity. Before you can begin gasless welding of aluminum with MIG, you should take some time and keenly examine the piece or sheet of aluminum that you want to work with. If you are working primarily with aluminum sheets, you should look for the best gasless MIG aluminum welders for sheet metal. If you notice any contaminants like dirt or lubricant, you should clean them off first. Aluminum is quite a corrosive metal that forms an oxidative layer when left in the open. It is therefore essential to scrap out this protective layer for every weld pass.

Many welders use a wire brush to scrub away the aluminum oxide. The most recommended type of wire brush for this is a stainless steel cup brush or a hand wire brush. Other steel brushes may have contaminants that would hamper your efforts. All the brushes will require manual effort, which takes up a lot of time and energy.

Using power wires is a better method of scrapping off aluminum oxide. You can set the number of revolutions per minute that you want and the pressure to clean the aluminum properly. However, any incorrect inputs in the settings may damage your metal surface by smearing it around, trapping contaminants where they are inaccessible. When doing gasless aluminum welding with MIG, it will be best to go for wire brushes that are designed specifically to clean aluminum.

If you want to maintain the chemistry of aluminum, you need to choose a wire that has a lower sensitivity to heat and crack. If this condition is met, you do not have to worry about this issue.

If you want to weld aluminum without worrying about burn-through, poor fusion results, and craters, you ought to ensure that your gasless aluminum welder is properly configured.

You may not achieve proper fusion if you move too fast or too slowly around the weld zone. This is because the high heat conductivity of aluminum keeps it from reaching the critical temperature required to fuse the pieces if your wire feed speed is too high or too low.

How can you guarantee that the gasless aluminum MIG welding machine supplies the required energy? Some MIG welders for gasless aluminum welding come with a feature to help regulate the energy supplied. Initially, the energy is boosted and slowly decreases if there is too much heat supplied. If you are unable to adapt to a better speed or regulate the voltage on your own, it is recommended that you get such a MIG welder.

Aluminum cracking due to stress is not as frequent as cracking under heat. Craters may appear small at first, but they spread quickly, compromising the weld irreversibly. If you want to find craters, look at the end of your weld zone.

To automatically fill the craters created as you weld, you should consult the user manual of your gasless aluminum MIG welder to find the crater fill function. You can also opt to increase your travel speed across the weld zone, which will reduce the rate of melting of the aluminum.

Finally, to avoid craters, you should choose a metal base that is not too cold.

When welding using a gasless aluminum MIG welder, it is essential to maintain the nozzle and tip aimed in the travel direction with a push angle between 10 and 15 degrees. Using a backhand technique or a drag angle, you may risk getting serious porosity and get a poor weld.

It is easy to detect when your wire does not feed smoothly. Using a gasless method of welding aluminum will require you to understand the causes of common problems and how to fix them. You can consult the user manual of your gasless aluminum MIG welder to help you troubleshoot and find remedies to any common problems you may face with the system.

For instance, contact tip problems can be caused by using the wrong tip to weld zone distance that may cause porosity and create an inconsistent weld. To fix this problem, you should ensure that the contact tip and the wire have matching diameters.

Now that you have gone through this guide, you understand how gasless MIG aluminum welding works and how to get the best results. When properly done, MIG welding aluminum without gas will create a clean weld for any cosmetic welding projects that you may have.

It is not enough to have the best MIG welder for aluminum; you should also know how to properly use the machine to avoid some of the setbacks mentioned in this article. This guide should give you the confidence you need to try out gasless aluminum welding with MIG today. Use the recommended techniques if you desire to achieve the best welding results when using a gasless aluminum MIG welder.