Spot welding is extremely cost-effective since you don’t have to think about filler metals. Nevertheless, the machine you pick for the job could still cause you headaches which is why you should always get the best spot welders for your budget that you can find.

That said, each spot welder’s capabilities depend on a couple of features, including the max welding current, input voltage, duty cycle, throat size, and more. Since you want your welder to provide you with a good user experience, you should ensure you consider each of these variables before you purchase the machine. The list below has taken most of these variables into consideration and thus should make choosing the spot welder model to acquire a lot easier.

Other features: 2.5 kVA @ 50% Duty Cycle, 6-inch throat, single-phase design, durable welding tips

One of the easiest spot welders to use in the market is the Stark Professional Spot Welder. It features a single-phase design, and with it, you can easily insert the metals you want to weld and join them permanently. Notably, it’s capable of welding up to 1/8” mild steel with its durable welding tips. Speaking of the welding tips, they’re made of high-quality steel materials, and the attached set isn’t the only set available. You get an extra set of tips, and if necessary, you just twist off the old and replace with the new. A handle is also included in the spot welder’s design.

Given the welder’s simple design and minimal controls, the Stark Professional Spot Welder works for anyone who wants an intuitive device.

Other features: 7 modes, 2 welding guns, efficient cooling system, dent puller

The Vevor G90E is another top-of-the-line spot welder and is designed to work with 110V sockets. The machine can work with metals in the 0.02” to 0.05” size range in terms of the welding thickness. Additionally, it offers a maximum welding current of 3500A. The device is fairly heavy, but the good news is that you needn’t worry about holding it up during use since the welding guns extend from the main body. Notably, these are multi-function guns, as shown by the seven use modes included in the welder. You can even use the machine as a dent puller for your car’s external metal panels. Lastly, the welder has an efficient cooling system.

This spot welder differentiates itself by having dent puller functionality and may work best in a car repair shop.

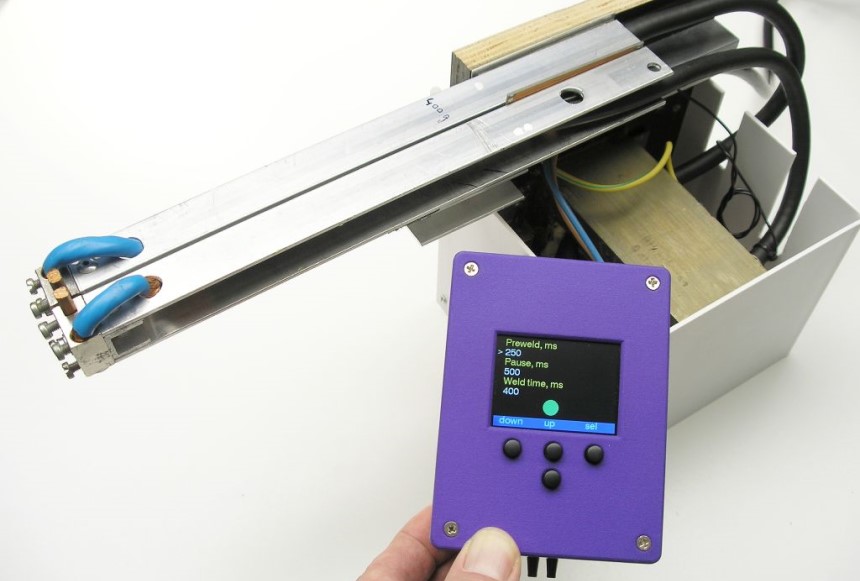

Other features: push up welding, pedal welding, distinct LCD panel, 4100 RPM radiator

As implied by the name, the Mophorn 737G Battery Welding Machine is another option best suited to welding battery packs. It connects to 110V sockets, and after that, it’s smooth sailing during use. Notably, the invention can be described as a push-up welding device because you’ll typically have to push your battery packs up against the welding electrodes. It also comes with a pedal controller that will free up your hands for other tasks. Another crucial design element is the inclusion of LCD panels. The upper panel shows pulse quantity, while the lower one will show you the current you’re working with. Of course, you have buttons to control these parameters as well.

This spot welder is for users looking for efficiency while welding battery packs.

Other features: 6 grades of output power, unique overheating protection, 16-inch welding pen

As far as portable spot welders go, the Kerpu Upgraded Spot Welder features one of the best designs in the market. It looks a lot like a smartphone power bank, even in terms of the functionality. For instance, it has a type-c charging port and stores power for later welding. Additionally, it comes with both a power indicator light and an output power indicator light. Speaking of the output power, there are six grades to choose from depending on what you’re welding. You also need to connect the welding pens to the spot weld pen interface before you can get to work. These welding pens are 16 inches long, so you have extra reach compared to alternatives like the Sunkko 788H Pulse Spot Welder and for a fraction of the price.

The Kerpu Upgraded Portable Spot Welder is for users who want a portable, effective, and affordable spot welder.

Other features: USB to Type-C charging interface, strong oxidation resistance, fire-proof and anti-fall; gold-plate welding pen

The BIFRC DH20 Pro Spot Welding Machine is one of the few spot welders in the market that offer real value. Its upgraded compact and lightweight design with more gear sets it apart. You can choose a suitable gear from the lowest (1 gear) to the highest (9 gear). The design also comes with a convenient USB to type C charging interface that offers a fast charging speed. Using the BIFRC DH20 Pro Spot Welding Machine is easy as ABC. You only need to press and hold the power button for about 3 seconds to power it on and the same for about 5 seconds to power it off.

Further, the BIFRC DH20 Pro Spot Welding Machine boasts a superior build quality. Its surface is ruggedly built with aluminum alloy which has strong oxidation resistance, is fire proof and anti-fall. As if that’s enough, you get a built-in high rate polymer power battery that outputs up to 650A and can produce enough power to weld thousands of points when fully charged. You will also love the gold plate welding pen that offers great conductivity and low resistance. To top it all, the BIFRC DH20 spot welder has multiple security safeguards that protect it from damages caused by extreme temperatures, voltage and currents.

Other features: upgraded LED lighting, precise pressure regulation, multiple USB ports

In its default configuration, the Sunkko 788H Pulse Spot Welder is mainly used for welding battery packs. It also has a precise pressure regulation feature so you can decide just how much pressure will be exerted while welding. This helps you work with metals of different thicknesses, although the maximum thickness allowed is 0.098”. Other parameters you can control include the pulse and current. There is even a pulse group setting knob included. Lastly, there’s the inclusion of three USB ports which isn’t something you’ll find in most other spot welders, especially at this price point.

The Sunkko 788H Pulse Spot Welder is for users who want precise control over pressure, pulse, and current while welding their battery packs.

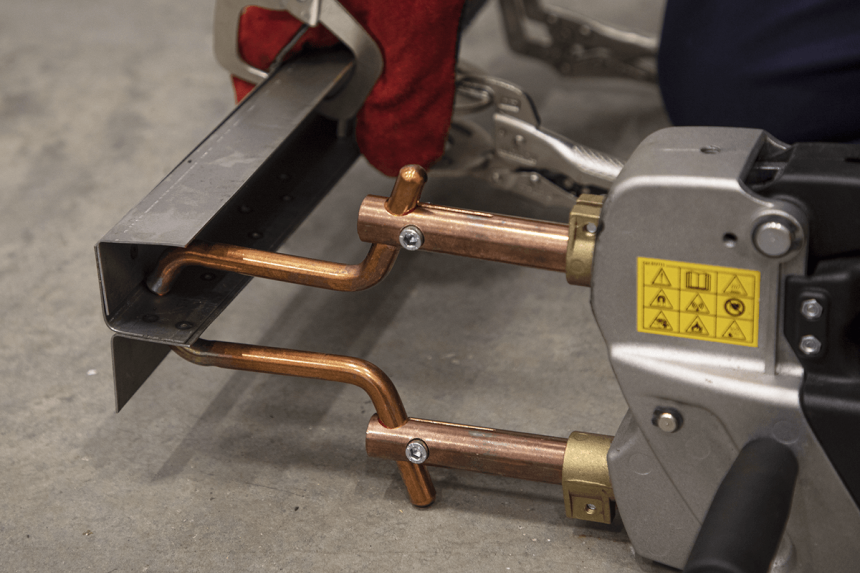

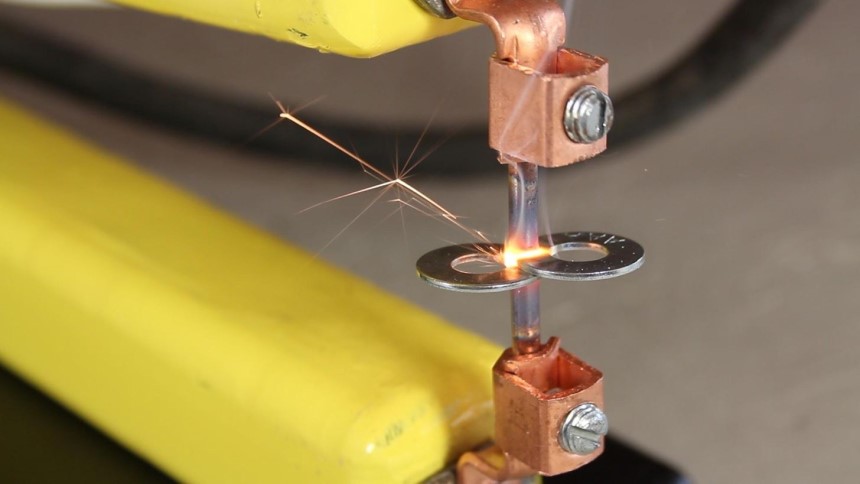

A spot welder works by delivering low-voltage but high-current electrical pulses to the workpiece using electrodes. The electrodes come in pairs, and the electrical pulses are meant to move from one electrode to the other through the metal workpieces.

Additionally, the metal workpieces in question tend to be poor conductors of electricity and thus will try to hinder the flow of electricity between the electrodes. Ultimately this will cause friction and heat the metal workpiece to more than 2000°F, which will melt the metal.

At this point, the electrodes press down on the workpiece, therefore, fusing the molten area. If the molten area consists of two metal sheets, they will coalesce into a single solid nugget.

Of course, the squeeze pressure may need to be maintained for a while, so the molten area remains fused until it cools.

Here’s precisely how to pick the best spot welders in the market.

Check the input voltage. In all welder types, the input voltage is one of the first things you check since you don’t want to make the purchase only to find the machine doesn’t work with your socket configuration. There are two variations of input voltage. One is 110/120V while the other is 230/240.

The latter is better suited for running high-power devices. As such, most 230V devices tend to be more powerful. That said, 230V outputs aren’t exactly common in North American households as according to World Standards Trusted Source Plug & socket types There are currently 15 types of domestic electrical outlet plugs in use worldwide, each of which has been assigned a letter by the US Department of Commerce International Trade Administration (ITA), starting with A and moving through the alphabet. www.worldstandards.eu , the type A and type B sockets used almost always have between 100-127V outputs.

Nevertheless, it is possible to change to a 230/240V system with the help of a qualified electrician. If the investment seems worth it or you already have a workshop with 240V outputs, you might want to consider machines like the Stark Professional Spot Welder.

If not, 110V machines like Sunkko 788H Pulse are a better fit.

The welding current or amperage often affects the electrode and the depth of penetration in the workpiece. As such, you always need to check the welding current and figure out how it will affect the metals you intend to weld with regard to their thicknesses. To be clear, your machine can’t weld effectively if the welding current is limited.

Often you don’t even need to calculate the thickness of the materials the machine can weld as the manufacturer provides this information. A list of weldable materials may also be provided, and you should check it out. That way, you don’t need to wait until it’s too late to figure out that the machine you bought doesn’t work with the metals or the metal thicknesses that you intend to weld.

If you want to find out how long your spot welder can operate before having to cool off, you look at the duty cycle. According to Weldclass Trusted Source Welding Machines - What is Duty Cycle & How is it Calculated? Your questions answered on duty cycle and welding machines! How is duty cycle is calculated? Is Duty-Cycle the best indication of performance? … and more! www.weldclass.com.au , the duty cycle is given as a percentage, and the amperage will also be stated.

For instance, you may have a 40% duty cycle at 180A, which would mean that in 10 minutes, the welder will work for four minutes before needing to cool for six. As such, the higher the duty cycle, the better for you.

Portability may also be another factor for some welders, especially if you offer remote services or prefer to work on the go. This is where machines like the Kerpu portable spot welder that fit in your pocket come in. However, not everyone places the same level of importance on portability, and some users may be okay with a heavy and difficult-to-move device as long as it gets the job done.

The power source is another consideration. Some need to be connected to a socket, others work on battery power, while others can even work with generators. Of course, if your workshop is generator-operated, you’re going to want a compatible machine. The same is the case if your workshop has 230V or 110V sockets. Battery-operated welders have the added advantage of portability, and coincidentally one of the best battery spot welders for DIY projects is the Kerpu portable spot welder.

Also, with most of the machines you buy, you tend to need a few accessories to improve functionality. These accessories can either be provided to you when you purchase the device, or you’ll need to look for and acquire them for a different price and at a different time. Getting them with the initial purchase can sometimes save you both money and time. Consequently, it’s beneficial to get a spot welder with multiple accessories included.

The warranty is the go-to solution for those who don’t want to lose money on their purchase. After all, given the number of welders that manufacturers produce a day, it makes sense that one or a few may not be the best quality. They might even exhibit some defects when new, and the warranty can get you a replacement or repairs without you needing to go deeper into your pocket.

Spot welders can be acquired for a wide variety of prices. As such, you have to look at the condition of your wallet before you can decide on a purchase. Nevertheless, even if you’re strapped for cash, you should avoid going too cheap as often it can mean a substandard purchase with limited functionality and a short lifespan.

Finally, see if there are any extra features you can get for your money, including options like adjustable power output, efficient cooling, LED lighting, LED screens, and more, as they’ll likely affect your user experience for the better. They might even improve functionality.

If you’re tackling a spot welding assignment, here are a few safety tips to ensure your wellbeing. First, wear safety equipment. This includes safety glasses, gloves, and maybe overalls. Next, ensure the foot pedal you use cannot be activated accidentally by having shrouds at the top and the sides.

Also, keep your hands away from the electrodes. Remember, the electrodes emit electrical pulses, and they can just as easily shock you. Lastly, it’s essential to get some training from a skilled instructor before you can effectively use spot welders. That way, you know how to do things like putting the metal sheets between the electrodes without hurting yourself.

With the Stark Professional Spot Welder, which is the editor’s choice, you can spot weld some fairly thick metals. Additionally, it has a relatively large throat, so you can fit your workpieces easily. Another impressive attribute is that not only does it come with durable welding tips, but you can easily replace them after they’re worn down by consistent use.

As a runner-up, the Vevor G90E Spot Welder is also impressive, especially with its extra features and functionality. You can even use it as a dent puller to repair cosmetic defects on cars and metal panels. Ultimately, its versatility may be worth your money.

The Mophorn 737G Battery Welding Machine is our third best choice because with push-up welding functionality and a pedal function, the Mophorn 737G is built for efficient battery pack welding and has the features to match.