Flux-cored wire welding is a great technique for all welders who often need to weld outdoors or on dirty material. It differs from MIG welding in that it does not require an external shielding gas such as carbon dioxide or argon to protect the weld pool from contamination.

You don’t have to worry about the shielding gas, as shielding gas does not necessarily have to be used with this type of welding. And best of all, it’s an ideal welding process for beginners. As there are many expensive models and the price doesn’t always guarantee quality, we have helped you select 10 of the best flux-cored welders under $200. We’ve selected them based on their welding processes, the voltage, output, duty cycle, accessories provided, warranty coverage, among others.

Other features: uses 0.30/.035 flux core wire; IGBT Inverter Technology; automatic compensation for voltage fluctuation; inner wire feeder

The YESWELDER Flux 135 ST IGBT is an excellent gas-less welding machine with built-in inverter technology. This model offers many extras including a high-performance voltage fluctuation feature, the inner wire feeder, and the IGBT Inverter Technology. It has a compact design and is easy to carry about. The machine uses a flux core wire of size 0.30 or 0.35. it has infinite wire speed and voltage control.

The machine has no cooling or overheating protection. However, it has a duty cycle of 60% at 135 amps and 100% at 104 amps. This means, when set at lower power, you’ll have no problem welding continuously. While welding at around 135 amps, you can weld continuously for 6 minutes without stopping and without the machine hearing up.

Other features: uses 0.30/.035 flux core wire; handles 2-pound flux core wire; built-in MMA function; smart digital display

The TOOLIOM T-135M is a multi-process welding machine that can make welding processes using metal inert gas (MIG), gas tungsten arc welding (TIG), shielded metal arc welding (stick), and more. It can weld 0.031 inches to 0.035 inches with a flux core cable. The welder is powered by a 110V or 120V household current.

Like the YESWELDER FLUX-135, it welds using 135 amperes or 104 amperes. It has a duty cycle of 60% at 135 amps and 100% at 104 amps. It can weld materials that are up to 1/8 inches.

Other features: variable feed speed control; 0.023” to 0.035” steel and carbon steel, 0.030” to 0.035” flux-cored wires

The SUPER DEAL PRO MIG 130 welding machine is suitable for high resistance welds. It allows MIG welding without the need for the gas cylinder, the gas being enclosed in the flux-cored wire. In particular, this enables high welding penetration. It is ideal for outdoor welding and even the presence of wind.

The flux MIG welding machine allows long continuous work and very clean cords as it has a maximum duty cycle of 35 percent. The welder uses cored wire that releases metal inert gas automatically while welding to prevent the welds from oxidizing.

Other features: built-in storage and heavy-duty cooling fan; uses 0.30/.035 flux core wire

The ETOSHA MIG 160 flux core welder is another gasless welder with IGBT inverter technology. It is a portable machine that runs on 110 volts with a welding gun and a ground clamp. It has an adapter cable for input power and a brush for cleaning. It has a synchronized adjustment function. Users do not need to match the operating voltage and feeder speed separately, so it is easy to use and can achieve a good welding effect.

ETOSHA MIG 160 welder uses 0.30 to 0.35-inch flux core wire. It produces an output power of up to 160 amps. This allows you to weld mild steel up to 1/4-inch. Designed with corrosion-resistant materials, the machine weighs only 39.7 pounds. However, it is almost three times as heavy as the ETOSHA MIG 140, which weighs 14.77 pounds.

Other features: built-in storage and fan; free welding helmet and wire brush; uses 0.30/.035 flux core wire

With a practical flux core wire for self-liberation of inert gas from metal during welding, this welding machine doesn’t allow the welded part to oxidate. It is a good option for hobby projects and home repairs in light steel. The welding machine can be used for mild steel as well as stainless steel projects. It offers a professional finish on fine steel welding or bodywork, while being efficient and powerful.

The VIVOHOME welder has 4 current flow settings as well as a 10-speed variable feed for perfect flux core welding of fine steel, stainless steel or aluminum, or thicker steel.

Other features: uses 0.30/.035’’ flux core wire; heavy-duty cooling fan

Stegodon MIG 140 is a flux MIG welder that can weld steel up to 1/4 inches. It has a heavy-duty cooling fan that helps with overheating as it has a low 20% duty cycle. It has a powerful capacity and uses the standard 0.30 and 0.35-inch flux core wire. There is a dedicated 110 voltage input power possibility. The powerful welder can weld mild steel, stainless steel, as well as cast iron.

The control mode ensures the reliability of the welding machine. It has a closed-loop feedback control, the output voltage is stable, and it has strong adaptability to the power grid. The welder has a comfortable handgrip, easy to start arc, allows to weld raw steel, white steel, ladder, metal cage, square tube, sheet metal. It is perfect for home DIY and outdoor repairs.

Other features: 4-level adjustable speed; built-in fan

Goplus MIG 130 is a flux-cored welding machine that can weld metal up to 1/8 inches. It comes with a welding mask that measures the size of 7.87 by 9.5 Inches. The welder has a 65-inch welding gun cable, a power cord, and a 10 A circuit breaker. There is also a 13A current fuse. The device has a maximum open voltage of 37 V and maximum absorbed power: 3.6 KVA. The maximum output current is 15% at 105 amp.

The product comes with accessories that help you start welding as soon as you receive it. The package features a welding machine, one welding gun, one welding wire, one welding mask, and one dust brush. The welding machine is an ideal tool for professionals and DIY enthusiasts alike.

Other features: uses 0.03-0.039 in flux core wires; suitable for 2lb and 10lb wire spool; IGBT power device with unique control mode; 85% efficiency

The Sungoldpower 190T is a flux core welder with dual voltage capacity. You can select from two input voltages of 110 and 220 volts. The output current can get up to 190 amps when welding in MIG. This welding machine can also process weld jobs using sticks as it is also an MMA welder. With this process, it can reach 200 amps. The duty cycle is 60% at 120 amps.

The majority of the other welders on this list use a transformer for the voltage controller, but this Sungoldpower welder uses Inverter technology for ion control. This gives it 2 advantages over other components. The first is a lighter weight of 34 pounds and the next is a lot more features.

Other features: inverter technology; free mask included

The Display4top MIG130 is a flux core wire gasless welding machine. It has automatic safety thermal protection, suitable for welding stainless steel, carbon steel, aluminum, etc. It’s a strong, durable, and compact MIG welder that is made of good quality stainless steel. Also, it’s painted with red paint.

There is an overload safety protection. With this, the welder automatically shuts off when it’s too hot and when voltage and current exceed the range. The feature keeps you and the welder safe. The internal cooling system helps cool the welder while it’s working.

Other features: IGBT technology; high-efficiency radiator

The S SIMDER MIG-140 is a metal inert gas welder, except that this doesn’t also use gas. The gas is in the wire and is automatically released while welding. This is also an inverter welder.

This tool is designed with all the important characteristics for perfect and efficient welding. The welder had a safety design that compensates for the fluctuation of voltage. It has overheating protection, under-voltage and overvoltage protection, and over-current and overload protection. Professionals should not do without this MIG welding machine. It is resistant, light, and efficient.

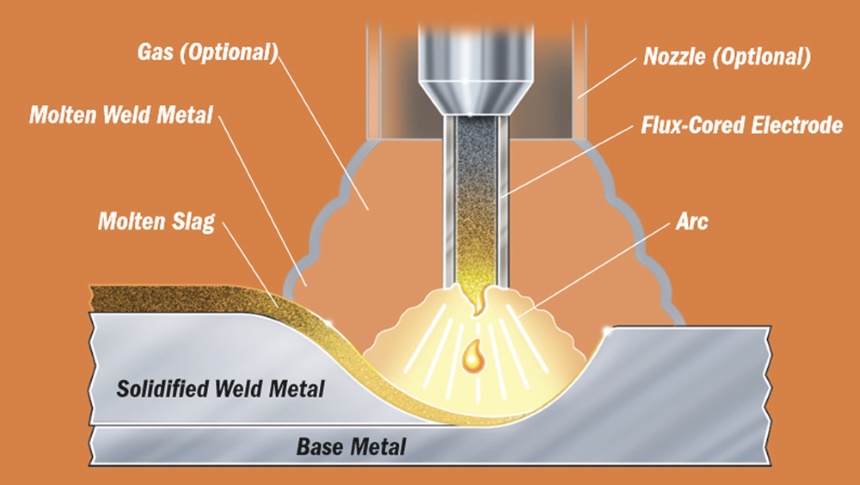

Flux-cored wire welding is an arc welding process in which a consumable electrode is used to generate heat. These electrodes are made of flux, filler material, and graphite to create the weld pool. Using these three components can reduce the amount of contaminants in the weld by removing slag and other contaminants from the molten metal during the process.

A flux core welder is a machine that was first invented in the 1930s Trusted Source The History of Welding | MillerWelds Welding has been around since ancient times. Read this article for a brief overview of welding history throughout the years. www.millerwelds.com . It lasted so long because it’s the perfect tool when you need to do welding work on metal parts. This type of welding machine does not require shielding gas and can be used on almost all types of metals such as aluminum, copper, steel, and more.

A flux-cored wire is a special type of wire in the form of a tube. The components of the electrode are on the inside. In the round rolling process, the components are stored in the tube. The embedded powder is responsible for protecting the weld seam – also called slag.

The functionality is initially the same as with most common welding machines that weld with electricity. A short circuit is created. The welding wire is fused with the materials to be welded, creating a weld seam.

In the so-called weld pool, the slag or protective powder floats upwards so that it surrounds the actual weld seam. This ensures protection from the environment and the air. With clean work, the result is a fine and flawless weld seam.

The special feature of the cored wire welding machine is that a so-called cored wire is used here. A protective layer is formed on the seam by the inner wrapped materials floating to the surface of the weld seam.

On the one hand, this protective layer protects the weld seam from aggressive environmental influences, such as moisture or acid. On the other hand, it prevents oxygen enrichment in particular, as this causes problems in weld seams. If environmental influences act on the fresh weld seam, this reduces the quality. In short: the weld seam is not as corrosion-resistant and durable.

Don’t confuse buying a budget-friendly product with poor overall quality. During our research, we found out that the models that cost more than $200 offer almost the same functionalities as the ones we picked. What differentiates these models are their brand names and maybe the longer warranties. Higher-end welders that cost more than $200 are made by recognized brands such as Lincoln Electric, Forney, and Hobart. But with models that cost less than $200, you’re going to have lesser warranty coverage, but the quality isn’t so average or poor. However, they’re not at par with the higher-end models.

The problem with this type of welder, however, is finding one that will fit all of your needs. So take a look at these criteria:

Before buying a welding machine, you should also look at the operating voltage. Most models can run on 110V, but some dual-voltage welders run on 110/120V or 110/220V such as the SUNGOLDPOWER MIG-190T and TOOLIOM T-135M. However, some machines can work on as many input voltages as possible.

The various filler wires should be usable with all welding equipment. A processable wire thickness of up to 0.8 mm must be possible. There are many factors to consider when choosing a welding wire. The most important considerations include diameter and weld metal quality. For example, cored wires for stainless steel range from 0.8 mm upwards like what you get with common sizes being 1.2 mm, 1.4 mm, or even 1.6 mm.

The amperage usually varies between 85 and 200 amps for this level of welders. The SUNGOLDPOWER MIG-190T can weld with an amperage up to 200 with MMA and 190 with flux-cored MIG. The amperage should be adjustable from 45 amps to 90 amps. When welding with filler wire, it is particularly important to set the amperage correctly. Even with a weld seam thickness of 0.8 mm or more, the amperage should be at least 90, because without enough current your work will not hold together properly and could even fly apart when heated.

The duty cycle is a percentage value over a given amperage. It indicates the welding and cooling time required for precise amperage. For example, the indication 70% duty cycle at 100A means that for 10 minutes of use, it takes 7 minutes of welding and 3 minutes of cooling.

So, the higher the percentage of the cycle, the better and longer the machine can run continuing without overheating. Meanwhile, if you’re choosing a low cycle model, choose one that has overheating protection.

A weight of less than 30 pounds is ideal. Usually, the rule of thumb applies here: the more power, the heavier the device. If you’re going to be welding on the go, choose a compact and portable welder.

Asides from the welder, most welding kits include a lot of accessories so you can weld like a pro or start welding as soon as the package arrives. The welder must come with the welding gun, one ground clamp, one welding helmet, one wire welding brush, and various other accessories.

We said it before, you can’t expect much from these devices. The first reason is the low price and the second is that the brands aren’t that established yet in the market and may not have the means to offer a longer warranty. However, ensure the product has at least one year of warranty and a month of return and refund policy.

Our Editor’s Choice is the YESWELDER FLUX-135. Rated 9.9 out of 10, this is an excellent gas-less welding machine with built-in inverter technology. This model offers many extras including a high-performance voltage fluctuation feature, the inner wire feeder, and the IGBT Inverter Technology. It’s therefore our overall best flux core welder under $200.

The TOOLIOM T-135M is our Best Value model. It is a multi-process welding machine that can make welding processes using MIG, TIG, MMA, and more. It’s therefore rated 9.8.

Also rated 9.8, the SUPER DEAL PRO MIG 130 is our best gasless welder. It allows MIG welding without the need for the gas cylinder, the gas being enclosed in the flux-cored wire.