Any experienced welder might know what pipe beveling is, but this doesn’t mean that a DIYer can’t try it too. If you want to weld two pieces of pipe together, what you need to do is bevel your pipe. Beveling is important in the process of joining pipes together, but there’s a lot to learn and consider to make sure you get the best weld joint possible.

In this guide, we would look at how to bevel a pipe Trusted Source Bevel - Wikipedia en.wikipedia.org for welding, how to choose the right one, and everything else you might need to know.

Pipe beveling involves creating an angle between the pipe and the surface it is supposed to be welded to. Beveling aims to ensure the ends of the tube are smooth and neat for safety. It also adds aesthetics to all welding procedures.

In layman’s words, pipe beveling is the process of changing the shape of pipes before they are welded so that they fit better. You can bevel pipes in different ways, whether with machines or a hand grinder.

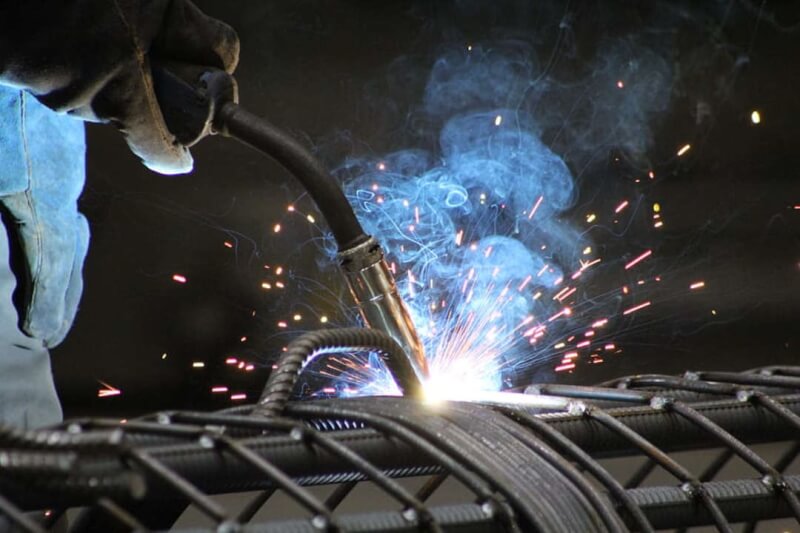

The whole point of beveling a pipe is to prepare the end of the pipe for welding Trusted Source What is Welding? - Definition, Processes and Types of Welds - TWI Welding is an operation whereby two or more parts are united by means of heat or pressure or both. It is used on metals, thermoplastics and sometimes wood. www.twi-global.com . If the shape is properly smooth, it can be easily connected to the surface. Beveling a pipe is also used to deburr the ends of cuts so that you can work safely, and for aesthetic effect.

Chamfering involves cutting a right-angled edge or a corner at an object to make a symmetrical sloping edge in carpentry. Chamfering, like beveling, is meant to make assembly easy and remove sharp edges to reduce the chances of injury.

Chamfering and beveling aren’t the same although they are often used interchangeably. Chamfering is a type of beveling, but while a chamfer is an edge that joins two surfaces at a 45-degree angle, a bevel is an edge that can be sloped at any angle except 45 or 90 degrees.

There are different ways you can bevel a pipe depending on what you prefer. Once you bevel the pipe as a form of preparation, you can weld the pipe. You can either use a hand grinder, plasma cutter, portable, or a stationary beveling machine.

With a hand grinder, you will also create a large mess and have to deal with safety hazards. Hand grinders also cause all kinds of inconsistencies, which can lead to a poor-quality weld when you finally collect the pipe to the surface.

If you still decide to use a hand grinder, you can check the manual that comes with it once you purchase and follow the steps to weld your pipe.

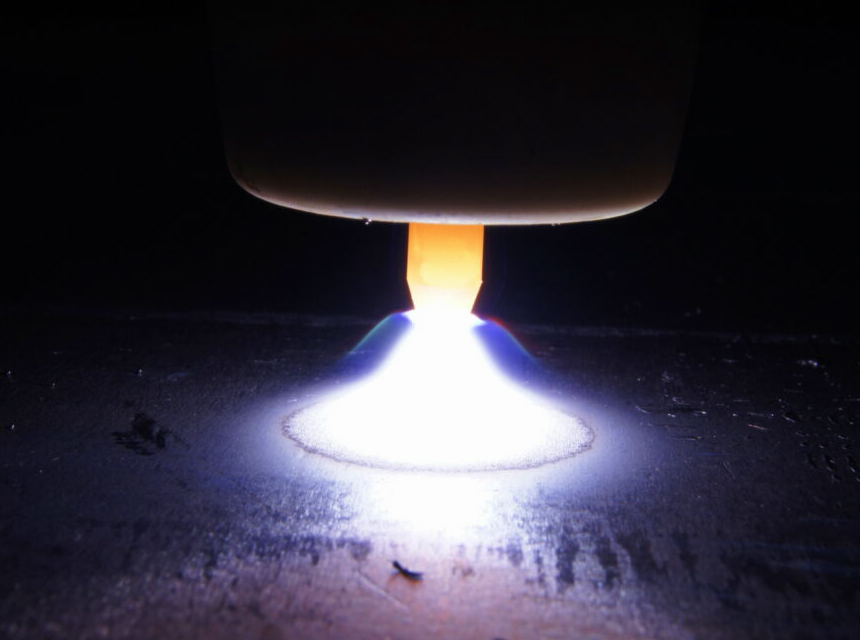

Another way you can bevel a pipe is with a torch cutter or a plasma cutter, but this method is also similar to the hand grinder and requires you to cut the angle with your hand. It’s advisable to use the cutter with a space-saving clamp-on machine so that you can guide the flame.

You will also have to prepare the flat land at the end of the pipe with your hand, which can be harmful, but you can do better with a good plasma cutter.

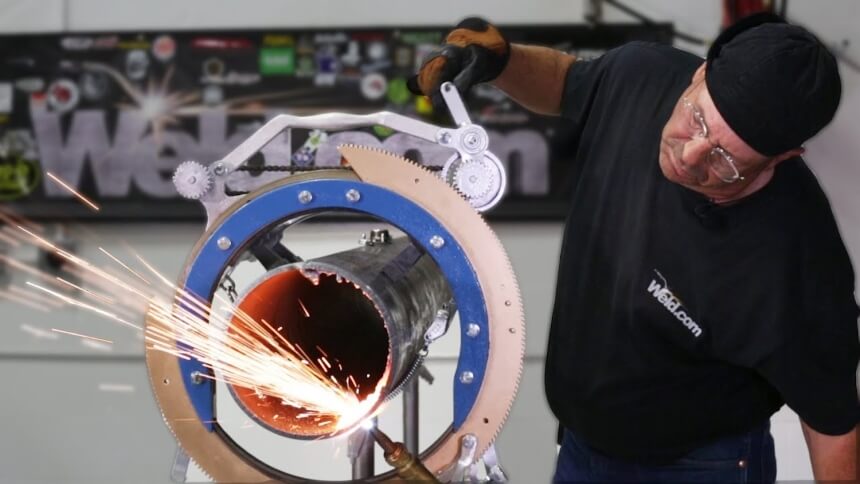

The machines are portable and easy to operate. They would also save a lot of time and produces a lot of consistent levels than the previous technique. You might have to deal with flying chips from the pipe caused by the machine and the electrical cords as a hazard. These tools can also be expensive, especially when they come with different features.

You can use portable beveling machines if you want to carry out maintenance work or you’re working at new construction sites. Some top-speed cutters in the machine can form angles on the pipe, with different slopes and angles. They can also come with clamps to keep the pipe in place when you are beveling it.

The final way you can bevel a pipe is with a stationary beveling machine, which would meet most of the requirements that you might need for professional beveling. You can create all kinds of bevels with the machine and it is used for high production.

Stationary beveling machines can be easily added to automated production lines and use low-cost carbide cutting inserts. The machine does not require any monitoring and can create all kinds of bevels, even J-bevels. Once you insert the pipe in the machine, it doesn’t rotate, and there is a drawer in it that collects all the metal shavings, so you don’t have to worry about making a mess.

The stationary machine works quickly but is usually more expensive. It is also safe, low-maintenance, and does not create a mess. The machine is easy to set up and can be used for all kinds of bevels, pipes, and tubes.

Apart from the different pipe beveling methods, you also have to consider the different kinds of techniques. The most popular beveling technique is the 37.5-degree bevel measure towards the face of the pipe. Other types of beveling techniques include the I-Type joint butt, V bevel, X bevel, J bevel, and U-bevel single.

The I-Type joint butt is the first one on the list, although it’s not exactly a beveling joint. Instead, the joint requires you to connect two pieces of popes to be joined together parallelly. You don’t have to create this joint at a particular angle, and it is sometimes mistaken with beveled joints.

The simplest type of beveling technique is the V bevel. This angle is created by removing the metal at the 45 degrees angle from the top to the bottom edge. When you bevel the pieces together, it creates a V shape, which implies the name.

Another beveling technique is the X bevel, which is similar to the V bevel, except that it’s a stronger joint. When creating the X bevel, you remove the material from both sides of the pipe, unlike with a V bevel where you remove only one side. You get half a steep in the angle than the V, which gives you a strong joint.

Although J bevels are as common as V bevels, they are also difficult to make, which is why you can’t make them with a hand grinder or a torch/plasma cutter. With a J bevel, you don’t cut from the top to bottom as you do with the V bevel. It also leaves a small piece of metal un-beveled in the weld area, meaning that the bevel isn’t straight.

As the name implies, the shape looks like J, with a slight curve at the bottom. Creating the J bevel gives you an even bonding layer and requires less material to fill it unlike with a V bevel. It is challenging to create too, but it gives you different benefits.

Although the Single U-bevel is the most expensive to produce, it is also the sturdiest joint and requires less material than the V bevel. But they have a radian shape, making it harder to manage it when welding.

When creating bevel joints, you also have to consider different technical specifications. So, you have to decide which technique and method that you want to use.

When choosing the right beveling method, there are different factors that you have to consider. These include:

Beveling becomes easier after constant practice, and as long as you’re using the right kind of machine that you need. It’s usually advisable to use a stationary beveling machine rather than other kinds, because of its multiple benefits. It saves money, time, and requires a very low skill level. It is also safe to use and can be used for all kinds of materials and techniques.

After considering your project, you should select the best options and start beveling your pipes before welding.