CAD welding is also referred to as exothermic bonding or thermite welding and entails binding cables using molten metal. CAD welding creates robust bonds without weakening their electrical attributes to form durable connections. This allows the installation of electrical protection systems that are stable all through their life.

Any other form of welding is subject to failure as other types of bonds may be weak. Additionally, the weld is free from contaminations that may cause corrosion or form a porous bond. Today we will discuss all you need to know about what is CAD welding and the CAD welding procedure. In addition, there are the best flux core welders that offer exceptional penetration that can suit attaching the thickest metals.

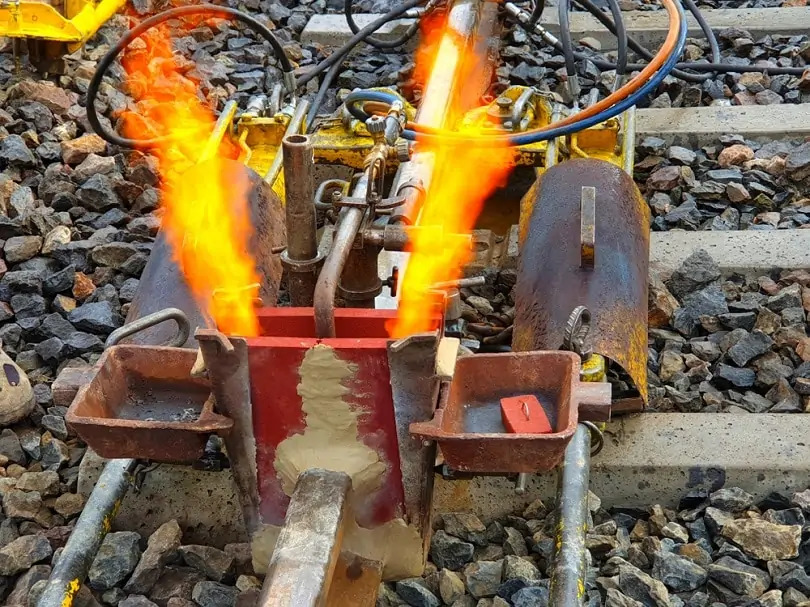

The Forney Easy Weld 140 MP is a multipurpose welder that can execute MIG, TIG, and stick welding. Nonetheless, CAD welding is commonly used to create bond sin steel reinforcing bars where CAD welding powder, widely called thermite, is fed into a hole that acts as a venue for combustion. It is then ignited using an oxyacetylene torch to connect the bars. This creates a strong bond as the powder used is pure metal that is free from contamination. The bond created is electrically sound and free from corrosion that may be present in other mechanical elements.

It happens in an enclosed joining environment that is hidden from visibility. It is mainly applied in large binding cables, for example, copper wires. If the connection was created using other metals or alloys, conductivity would be tampered with and reduce its lifespan. CAD welding is also applied in rail tracks, underground grids, and CAD welding ground wires. This is essential as mechanical contraction joints are subject to failure after some time.

Here are some of the attributes of the bond created during the CAD welding process:

After understanding what CAD welding entails, let’s look at how to cadweld. The term exothermic originates from Greek which means chemical reactions to produce heat. Reactions between iron and oxygen are exothermic but create heat that is rarely notable. However, CAD welding utilizes highly exothermic reactions where temperatures reach up to 2,000 degrees.

It is mostly applicable in welding lightning safety and earthing where conductors bond to create a firm connection. It is also effective in different binding metals such as weld copper, copper alloy, and various types of steel alloy. The best welders for aluminum offer exceptional speed and precision for outstanding weld results.

As stated earlier, the process does not require external heat sources, and the process takes little time. It requires thermite powder and a reaction to ignite the conductors. A heating torch is needed to kickstart energy activation so as to commence the CAD welding process. After cooling, the exothermic reaction will result in a stable resistance and mechanically firm bond.

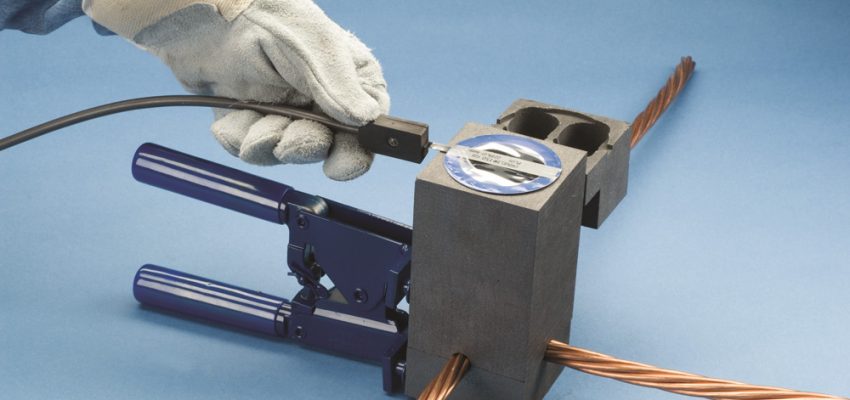

The process requires several welding paraphernalia such as CAD welding powder, handle cramps, and molds. Molds are deployed to position the welds where the sealing compound is poured at the reaction point. This inhibits the escape of any weld metal. Base metals should be cleaned before the process to avoid contamination. The reaction causes the molten metal to pour into the cavity, forming a strong bond between the two metal pieces. After adjoining, the clamp is removed, and the joint is left to cool.

The prominent types of CAD welding include rail welding and cadweld, as discussed below:

This is a more self-contained welding process as compared to rail welding. This is because the filler metal and activator are preliminary measured. Hence, you will not be required to measure the amount needed for each weld.

Additionally, copper oxide and aluminum have a controlled reaction to produce molten copper and aluminum oxide. The pure copper bar should be positioned at the middle of the graphite mold cavity. Position the isolation washer at the reaction chamber to inhibit the spitting of the mold cavity. The mold is then closed and the clamp locked.

Fire the gun with a heating torch to chemically react the powder. The copper melts and pours into the cavity to bind the two bars.

It utilizes similar equipment as discussed in how to cadweld above. Nonetheless, rails are designated to serve locomotives that require larger cables and copper bars. Hence, the equipment to be deployed has to be larger as well.

Molds are large and positioned on both sides around the designated joint area. But it differs in ordinary CAD welding as the reaction does not happen within the mold. The thermite is reacted separately, and then the molten metal is flown in the binding area.

The mold is then uninstalled from the joint region before it extremely cools. This enables the eradication of the excess projections by hitting with a hammer. A grinder is then used to smoothen the joint to prevent leaving any protrusions.

Its usage has been utilized in a wide sheer of industries over the decades. Below are some of the renowned applications.

Exothermic copper welding utilizes copper oxide and aluminum to weld copper. It mimics the steel welding process but differs in that the graphite molds can be reused. It is mainly applied in binding conductors in various industries such as vehicle bars, electrical power distribution, and so forth. Other applications include welding transit rail tracks to provide stable low resistant electrical conductivity. Pure metals are recommended as they may result in weaker joints.

This involves binding wires with a wide sheer of alloyed metals and solders. It is similar to exothermic reactions as filler materials, and metal oxide is incorporated to create a reaction. The process involves igniting for a short span so that the sensitive electric parts are not damaged. This reaction melts the workpiece surfaces, which enhances the joining of the pieces with wet alloy.

They are deployed in micro electric packaging, petrochemical parts, aerospace equipment, among others. It is mostly utilized in binding components that have varying thermal expansion because of the short-lived heating that causes insignificant distortion.

Based on the National Electrical Code Trusted Source Codes and Standards | NFPA Adopted in all 50 states, NFPA 70, National Electrical Code (NEC) is the benchmark for safe electrical design, installation, and inspection to protect people and property from electrical hazards. www.nfpa.org , one can only utilize exothermic welding to bond copper and galvanized cables as galvanized components do not have great conductivity compared to other metals coated with zinc. Additionally, any other form of welding can result in porosity, among other defects which do not occur when utilizing exothermic welding.

CAD welding has numerous applications where benefits and drawbacks can be observed, as discussed below:

Exothermic bonds are more sustainable as compared with mechanical ones. This primarily applies when binding conductors. They form a durable bond that is adamant to deforming and weakening. It is also a fast and easy process that one can quickly learn.

It also has the potential of welding numerous materials such as copper, brass, bronze, and so forth. This creates a connection that is free from corrosion and non-porous.

Though CAD welding bears exceptional advantages, there are some potential drawbacks, such as being hazardous. This entirely relies on the technique used in welding. The VIVOHOME MIG Welder 130 Flux Core has an on/off safety control that inhibits possible damages during MIG welding.

Below is a table that outlines the benefits and drawbacks of CAD welding.

| Advantages | Disadvantages |

|

|

|

|

|

|

|

CAD welding powders contain fluorides, copper, and copper compounds.

The ignition temperature in thermite welding is roughly 2,200°F. However, high temperatures may be utilized depending on the materials being bonded.

You cannot execute weld cads in the rain or within much moisture. Additionally, the wind is a great hindrance when CADS welding.

So, what is CAD welding? According to All-State Career Trusted Source Why Welding is an Important Industry | All State Career The welding industry is not for everyone, as it is a very physically demanding and challenging job. www.allstatecareer.edu , CAD welding is an imperative aspect of modern metal fabrication. This is because it serves a substantial scope of the world industries. This article has discussed what CAD welding is, the types of CAD welding, and how it works.

We have also articulated its applications in copper, electronics, and galvanized cable. Though it has numerous advantages, such as durable and non-porous bonds, it may also be hazardous based on environmental settings. TIG and MIG welding professionals should dwell on the best welders for sheet metal with outstanding efficiency, duty cycle, among other features.