All professionals use various types of tools, tricks, and methods to perform their duties. Metal dealers use welding machines and bolts to join different pieces of metals, while plumbers use pipe joints to connect pipes. Metal fabrication is a profession that requires several years of training and apprenticeship to master the art. Metal fabrication involves welding and riveting, and most people find difficulties in differentiating between riveting vs welding. There are several factors to consider when choosing between rivets vs welding. Some of the factors include safety, cost, and material.

North American countries prefer welding, while European countries prefer using rivets to join two pieces of metals. These joining technologies have advantages and disadvantages. Therefore, companies should use the procedure that meets their needs.

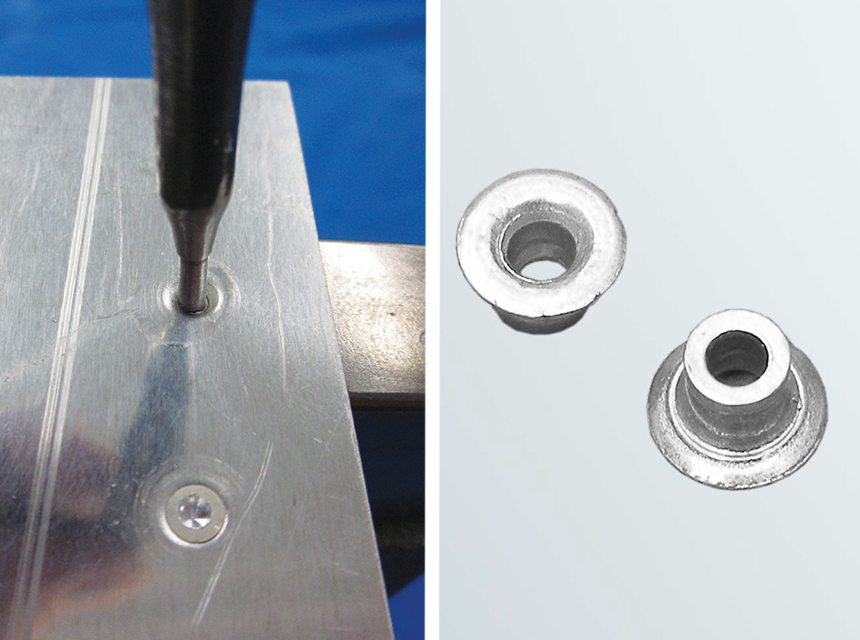

Riveting involves the use of a mechanical fastener known as a rivet to join parts of a metal. The rivet consists of a head on one side and a cylindrical tail. It resembles a metal pin that one uses to join metals to metals or other surfaces such as wood.

Rivets function similarly functions to that of bolts and nuts. However, one cannot remove a rivet by unscrewing it. One needs to break or destroy the rivet before removing it completely. The rivet's design Trusted Source Experimental Strength Analysis of Riveted Joints Using Blind Rivets | Sciendo This article presents results of experimental investigations of the lap blind riveted joint. The main goal of the work is determination of destructive load of the blind riveted joints. sciendo.com was to provide permanent or semi-permanent joints.

To install a rivet, one places the rivet in a drilled or punched hole. Once the rivet is inside, one bends or deforms the tail end, expanding 1.5 times from the original size. It forms a new head on the tail, which holds the two metals together. People refer to the deformed part as a shop head and the original charge as the factory head.

There are several rivet types in the market. It is important to understand the uses of each type of rivets and their application. The different types of rivets include:

Solid Rivets

Solid rivets have existed for the longest period. Most people refer to them as round rivets. The fasteners have a basic design that consists of a shaft and head. One can deform the shaft using a hammer or a rivet gun. Another tool that can deform the tail of round rivets is a rivet compression or cramping tool.

Structural engineers propose the use of solid rivets in constructing permanent structures such as:

Metal fabricators prefer fasteners because of their high safety levels and reliability.

Tubular Rivets

Tubular rivets resemble the shape of solid rivets. However, it has a partial hole at the tip of the shaft. Some people refer to it as semi-tubular rivets. The hole at the tip reduces the amount of force exerted when rolling the tubular part outwards. Tubular rivets require ¼ of the force required to drive in a solid river. People use Tubular rivets mainly in aluminum ladders, lighting, brakes, and HVAC ductwork. Tubular rivets are made using different materials such as copper, aluminum, brass, and steel.

Pop Rivets

Also known as blind rivets, they consist of a rivet and a mandrel at the center. People use pop rivets when they cannot see the backside of the metal sheet. When joining, one enters the rivet through the tight hole on the material you intend to join and uses a rivet tool to pull out the mandrel through the fastener.

The force between the mandrel’s head and the tool increases the diameter of the tail hence joining the two sheets of metal. There are three types of pop rivets: self-drilling pop rivets, speed fastening, and self-tapping pop rivets.

Pop rivets have several uses such as:

Drive Rivets

Drive rivets are similar to blind rivets. However, they have a shorter mandrel compared to the blind rivet. Installation of drive rivets involves hammering the mandrel into the rivet body to increase the shank’s size and ensure a stronger grip. Most home designers use drive rivets to attach architectural features to walls. They offer the best option when not needing to create a hole on the entire sheet.

Split Rivets

Split rivets are special self-piercing rivets with unique shapes and designs. They have a split tail and smaller heads. Some people refer to them as bifurcated rivets and use them on soft materials such as wood, plastic, and leather.

Oscar Rivets

Oscar rivets resemble blind rivets. However, the hollow shafts in Oscar rivets have split. The splits come in three sets to allow the shaft to bend outwards when driving the mandrel into the rivet. The bent part crates a broader surface that prevents the shaft from pulling out.

Flush Rivet

Most people use flush rivets on exterior surfaces to improve the overall appearance and reduce aerodynamic effects. Some refer to it as countersunk rivets because of the countersunk head and holes.

Rivets are used to strengthen and provide stability to structures since they offer permanent joints. Riveting is popular among construction workers to help join different parts and attach sheets to walls. But still, this process has its upsides and downsides.

Pros

Starting from benefits, riveting offers a cheaper alternative to other metal joining technologies such as welding and adhesives. They do not involve the use of electricity or special devices to create a connection. Also, this process does not require a lot of preparation. It uses less equipment and produces minimal waste after riveting, reducing production costs and increasing output. Moreover, rivets come in different designs and shapes to suit different needs. People can use rivets to join dissimilar materials such as plastic, ferrous, and nonferrous metals. In addition, rivets are highly durable and provide permanent solutions. They are made using high-quality materials such as steel, nickel, titanium, and aluminum which are resistant to corrosion, chemicals, and moisture. As for damaged rivets, they can be easily installed and require simple tools to reinstall a damaged rivet. Finally, removing rivets does not cause damage to the material.

Cons

However, there are some downsides. First, the process requires a minimum of four people, increasing the workforce and total labor costs. Second, rivets have their weight, which adds to the weight of the metal parts. The added weight affects the efficiency of the rivet. Third, one can easily notice rivets from a distance. Rivets decrease the overall aesthetics of a structure. Lastly, rivets require pre-drilled holes, and joints made using rivets are not leakproof.

Below are the advantages and disadvantages of riveting.

| Pros |

Cons |

| Riveting is more cost-effective | Riveting requires more workforce |

| Riveting provides enhanced production output by using less equipment and producing minimal waste | Rivets increase the overall weight of the metal parts |

| Rivets come in different designs and shapes to suit different needs | Rivets decrease the overall aesthetics of a structure |

| Rivets are highly durable and provide permanent solutions | Rivets require pre-drilled holes |

| Rivets do not require frequent inspections | Joints made using rivets are not leakproof |

| Removing rivets does not cause damage to the material |

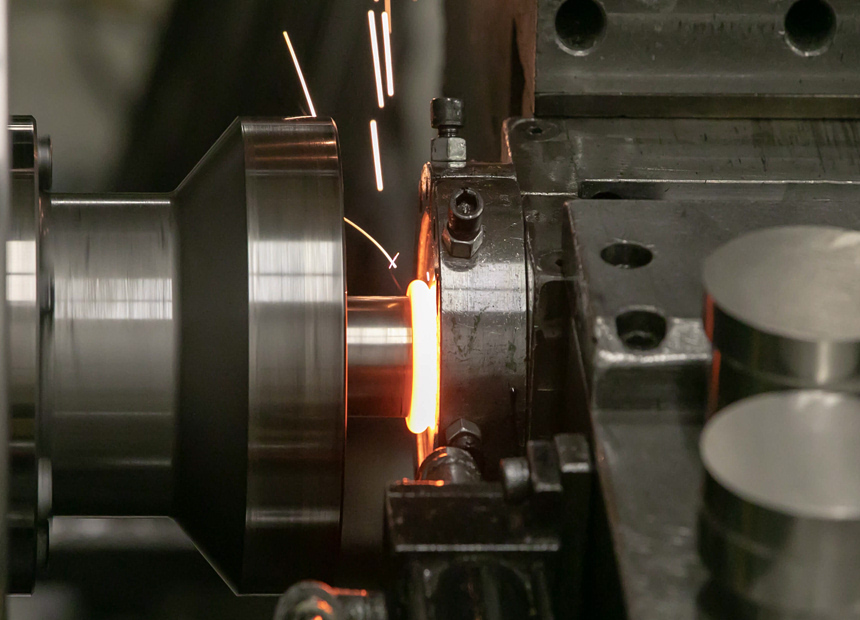

Welding is an alternative process to riveting. It also offers a permanent fabrication procedure to join two metallic parts. The welding process uses thermo-softening technology that causes the metal to soften through heating and hardens by cooling.

Welding is used to joining metals and thermoplastics. The process uses particular types of equipment, such as the Multi-Process Welders. The kits use electricity to produce heat that melts the metal parts and fuses them by cooling.

The melting action uses heat produced by connecting the spot welders to electricity. A filler material is used at the joint to create a weld pool. Once the weld pool cools down, it forms the joint based on the configuration. The pressurization of the pool makes it stronger than the base metal. Welding requires protection so that the filler used is not contaminated.

Several types of welding include:

Arc Welding

Arc welding involves several manuals, automatic and semi-automatic processes. This welding procedure joins stainless steel, cobalt, aluminum, and copper alloys, applicable in aerospace, oil, gas, and power companies.

Friction Welding

This procedure uses mechanical friction to join parts. This feature allows it to be used in different materials such as steel, aluminum, and wood. The mechanical friction softens the base material, mixing and creating a strong joint after cooling. It does not require any filler, flux, or shielding gas. It is best for use in aerospace industries since it can join lightweight aluminum parts.

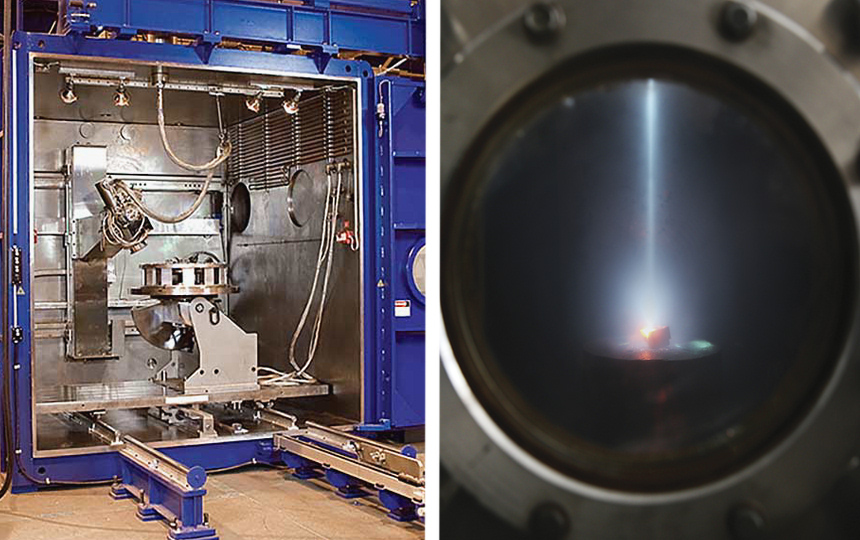

Electron-Beam Welding

Electron-beam welding uses the welders for sheet metal, producing high-velocity electronic beams to heat and melt the base material and join it to another piece. The process is conducted in a vacuum to prevent the beam of electrons from dissipation. It is best for use when joining thick metal sections.

Laser Welding

This kind of welding is mainly used n the automotive industry. It works by concentrating high heat on the joint, making it ideal for deep and barrow welds. It is quicker compared to other types hence used mainly in high volume applications.

Like any other process, welding also has some advantages and disadvantages. The table below illustrates the spot welding vs riveting advantages and disadvantages of welding.

|

Pros |

Cons |

| Welding does not add to the overall weight of the structure | Welding requires skilled labor-one needs training and experience to master the art |

| Welding provides a more efficient process | Poor heating and cooling can lead to distortion and weak joints

|

| Welded materials have better aesthetics | Welding is prone to cracks |

| One can perform modifications easily | Welding requires a thorough inspection to notice the defects |

Deciding between a rivet vs weld can be a difficult task. Both processes offer one the ability to join two different parts. However, several considerations can help you choose between the two.

Complex processes will require welding rather than rivets since welded joints are stronger than rivets. However, welding might change the structure of the base material such as aluminum, especially in planes, which can pose a massive threat to overall safety. According to a report by Science Daily Trusted Source Airplane Riveting Improved With New Technology | ScienceDaily Researchers at the Fraunhofer Institute for Manufacturing Technology and Applied Materials Research IFAM in Bremen are experts in adhesive techniques and plan to enlarge their expertise to include mechanical joining. www.sciencedaily.com , plane construction uses rivets to join parts.

Welding is more convenient since it does not require drilling holes and performing calculations to determine the number of rivets to use. According to different reviews, the Tooliom 200A MIG welder performs several functions, making it convenient for welding purposes.

Riveting can be performed on different types of materials, including plastics and wood. Welding is restricted to metals and thermoplastics. Riveting offers a better option when joining non-metallic parts

Welded joints are safer than rivet joints since it is stronger when considering the forces that could draw the joined parts apart.

However, the welding process is not safe when done by an unskilled person without any supervision.

Several studies Trusted Source Welding: Health risks from welding | HSE Both acute and chronic health risks are associated with welding fume. Occupational lung disease, including lung cancer, is the most common health risk, but welding can also affect the eyes and skin. www.hse.gov.uk also show that welding has several health effects. The Mophorn MIG welder is an easier to use and safe welding machine that one with little experience in welding can use.

The heating process and drilling holes take more time. Welding does not require all these preparations.

As seen above, different scenarios will require different technologies for joining parts. However, one should consider several other factors before choosing between welding sheet metal vs riveting the sheet. These factors include:

One should check whether the two parts consist of the same material. When joining different materials, it is best to use riveting.

It is important to consider the type of joint required. Welding offers the best permanent joint that does not require frequent repositioning or replacement.

Welding provides stronger joints compared to riveted joints. Welded joints can withstand more pressure than riveted joints.

Rivets are prone to corrosion that may lead to damaged joints. Welding is more resistant to rain, dust, and corrosion.

Welding and riveting are different mechanisms used to join pieces of metal applied in different scenarios. Below are the main differences between welding and riveting.

|

Riveting |

Welding |

| It requires one to drill holes on the base material to insert the rivets | No drilling of holes o the base material |

| A lot of time is spent while drilling holes | Takes less time |

| Riveting adds to the overall weight of the structure | Welding does add to the overall weight of the structure |

| High load capacity may weaken a rivet joint

|

A welded joint is stronger and may withstand high pressure |

| Base composition remains unaffected | Welding affects the base composition of the metal base around the welded part |

| Riveted joint remain firm in a high vibration environment | Welded joints do not perform well in an area with high vibrations |

| Riveting need several accessories such as rivets and straps | Welding does not require any additional strap, and a filler material is only used to connect large gaps |

| Anyone can insert a rivet without any formal training | Welding requires a high level of training and apprenticeship to master the art |

Welding and riveting are essential procedures used in several manufacturing and construction industries. Both of them are used to join different parts to produce a strong and stable structure. However, the choice one picks depends on several factors, from safety to durability.

The answer to the question ‘Riveting vs welding: which one is the best?’ depends on the scenario that involves joining two parts. Welding is best for producing strong and durable joints with a high load capacity. Rivets produce a strong joint, but heavy loads might damage the joint.

We hope this article helped you to choose between these two procedures!